Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do today-2024

- Thread starter CDNflatlander

- Start date

WOO HOO!!! What a great feeling that first drive is.Lincoln saw daylight today after 4-1/2 yrs in the shop. Shakedown went well. very happy. a few small issues to take care of but all in all a great day!

View attachment 10687

Car looks great…stance is perfect…nicely done…how does it ride?..

Excellent! That must of been Great Lee! Looks fine from here

Rides nice. didn't get past 40mph though, tuner says take it easy not to go into boost before we install the bigger injectors on the dyno. The hydroboost brakes and steering are great, but when I shut off the electric pump the pedal goes to the floor. That is not good. Looks like another round of bleeding the brakes. From what I hear I am not the only one with bleeding issues on wilwoods. Also the electric fan kicks in at 202F ,which is where the coyote likes to run and it is extremely LOUD. At the advice of my ford performance guy ,I am changing the thermosat today from a 195 to a 170. He said it should run around the 185-190 range . Still have to calibrate the cruise and the speedometer ,but all in all a fantastic day.

Saturday, March 23, attend the Red Deer swap meet…2 pavilions of tables and toys to ogle at. Yes there were lots of speed parts…and some other stuffs.

Got on site for 11am (doors opened at 08:00), and had enough walking looking and visiting by 1:45. It might just be me, but it seemed like the crowd was done by noon, only a few stragglers and visiting types after 1:00.

Brought home a work stand to use in the shop and a few ideas for projects on the go.

Got on site for 11am (doors opened at 08:00), and had enough walking looking and visiting by 1:45. It might just be me, but it seemed like the crowd was done by noon, only a few stragglers and visiting types after 1:00.

Brought home a work stand to use in the shop and a few ideas for projects on the go.

Thak you for your report.Saturday, March 23, attend the Red Deer swap meet…2 pavilions of tables and toys to ogle at. Yes there were lots of speed parts…and some other stuffs.

Got on site for 11am (doors opened at 08:00), and had enough walking looking and visiting by 1:45. It might just be me, but it seemed like the crowd was done by noon, only a few stragglers and visiting types after 1:00.

Brought home a work stand to use in the shop and a few ideas for projects on the go.

Yes, I have noticed that too at some swaps, crowds done by 1.

Greg: You got there at 11:00, were ready to go by 1:45, that's 2 hours, 45 minutes. So, how surprising is it that the majority of the guys that were there are already gone by noon, that's four hours after the doors openedSaturday, March 23, attend the Red Deer swap meet…2 pavilions of tables and toys to ogle at. Yes there were lots of speed parts…and some other stuffs.

Got on site for 11am (doors opened at 08:00), and had enough walking looking and visiting by 1:45. It might just be me, but it seemed like the crowd was done by noon, only a few stragglers and visiting types after 1:00.

Brought home a work stand to use in the shop and a few ideas for projects on the go.

Am also fighting to get a good pedal (bleed) on my Wilwood MC - looking for others with wise words of wisdom, came across this on the H..B.Looks like another round of bleeding the brakes. From what I hear I am not the only one with bleeding issues on wilwoods.

May have to go to extremes it seems to get that darn air out LOL

Yeah, John, If i could fit a corvette MC in there I'm sure I would be fine . My brother is coming out in a couple days , I will stock up on brake fluid and will pump the crap out of it until its done. hahaAm also fighting to get a good pedal (bleed) on my Wilwood MC - looking for others with wise words of wisdom, came across this on the H..B.

May have to go to extremes it seems to get that darn air out LOL

View attachment 10719

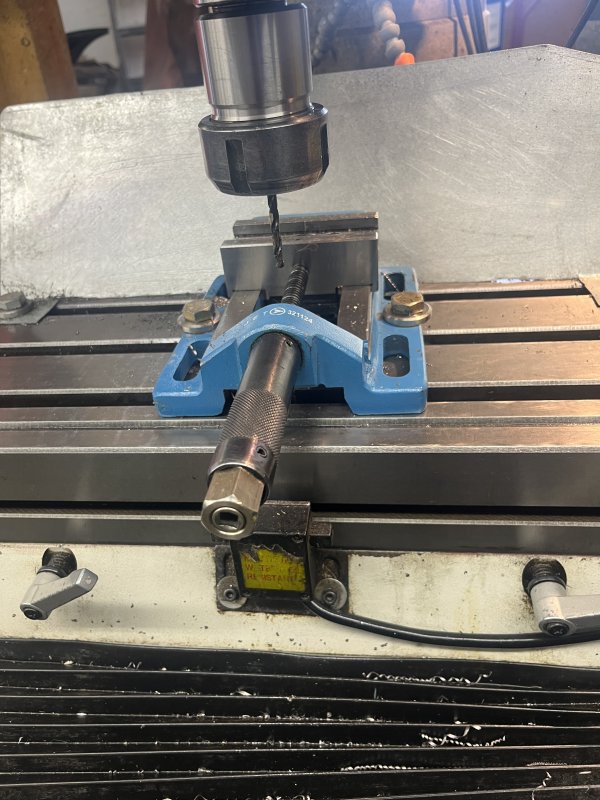

Shop day, great day. Started with buddy coming over (the guy I am helping with on Wednesday evenings, 53 GMC); we needed to cut out and bend up his steering shaft stabilizer mount. Pretty simple task with a plasma and a hydraulic press.

He left at noon for his family ‘events’, so I moved onto personal projects. Wife’s happy face license plate holder, amateur radio ‘case’ for an antenna ‘dummy load’, mill vise-wrench or ratchet drive-end. Then onto testing for ‘engine turned’ materials, aluminum, brass and stainless.

Now an ‘Old Fashioned’ to settle out the night.

He left at noon for his family ‘events’, so I moved onto personal projects. Wife’s happy face license plate holder, amateur radio ‘case’ for an antenna ‘dummy load’, mill vise-wrench or ratchet drive-end. Then onto testing for ‘engine turned’ materials, aluminum, brass and stainless.

Now an ‘Old Fashioned’ to settle out the night.

Next, back onto the ‘55 reassembly for spring.Shop day, great continued; amateur radio ‘case’ for an antenna ‘dummy load’, cut then drill and tap for the clear acrylic sides & back.

Attachments

For engine turning, try a round SS brush (that looks like Bart Simpsons hair) with O-rings to hold the bristles tighter with valve grinding compound or rubber (like a pencil eraser) with valve grinding compound. That is how I used to do it on gun parts. I liked the brush better as you can adjust the diameter with pressure as the bristles splay out AND the brush worked better on convex surface (like a rifle bolt). You could use a stiff felt as well, anything the size you want that is somewhat stiff but still pliable and let the grinding compound do the work. Gives a nice fine "jewel".

Thanks Cody! The aluminum piece was done with a SS brush…I will try adding o-rings for diameter control as well as lapping compound.

Thanks for the feedback!

Thanks for the feedback!

I know I mention "felt" in my previous post but have never tried it personally. However, it occurred to me at about 3AM, for a source for said felt, that punching out discs the appropriate size from an old cowboy hat and gluing them to a spindle would probably work quite well on flat surfaces (with lapping compound of course). One old hat from Salvation Army or some such would last a lifetime.

Or, if you're lucky, maybe the felt pads for the bottom of legs on furniture they sell to protect your floor might have the O.D. you need, but if they're too big, you can always use your gasket punch set to get the O.D. you want.......

https://www.realcanadiansuperstore.ca/search?search-bar=felt pads

This pkg is $2.00/16pcs

This one is $3.00/104 pcs

And of course, because it has 3M on the pkg, this one is $6.50/16 pcs

https://www.realcanadiansuperstore.ca/search?search-bar=felt pads

This pkg is $2.00/16pcs

This one is $3.00/104 pcs

And of course, because it has 3M on the pkg, this one is $6.50/16 pcs

Wednesday evening, work over at buddy’s shop consisted of steering shaft stabilizer. He had come and plasma cut it last week, we also formed it for the structural support, tonight was fitting it and welding it out. The unit bolts to the S-10 frame utilizing existing bolts.

Several other actions to line up for next steps took place; glove box latch opened, donor seat seat track adjustment tested, and brought the box/fenders in from the ‘bank’…snow bank it was positioned in for last several months.

Several other actions to line up for next steps took place; glove box latch opened, donor seat seat track adjustment tested, and brought the box/fenders in from the ‘bank’…snow bank it was positioned in for last several months.

I did some work on a friends project today. He bought himself an older build 32 Brookville body roadster, tore it all apart and now has decided to change everything. Now Running a 502, tremic 5spd, swing pedals and a 5 inch drop axle. So made him up a new firewall, floor pans and trans tunnel.

I did some work on a friends project today. I’m guessing that it is an automatic trans?