Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sassy the 64 Moy Caliente Comet

- Thread starter Sassy

- Start date

This is what I use. Having said that it might be to costly for some but I do a lot of weld repairs that are open to atmosphere and cant be pressure tested. Just repaired my oil pan on the coyote and welded oil return bungs for the turbos and spotted a pin hole on one of the welds. A must have product for me. There is nothing more aggravating than finding a slight leak in an oil pan after it is sealed on the block and full of fresh oil. You simply spray the white developer on the outside of the pan covering the weld area and then spray the red dye penetrant on the inside of the same area. the obvious pinhole or crack will appear immediately but leaving it for an hr. or so is best to reveal any cold lap in a mig weld .

https://www.vallen.ca/products/220-...t-developer-standard-12-oz-aerosol-can-cloudy

https://www.vallen.ca/products/220-...t-developer-standard-12-oz-aerosol-can-cloudy

Last edited:

The other leak I had was the front seal,,,,, so I thought!

Thank goodness the piece in the crank wasn't tight!

Get reading and I guess that bolt is one time use and Ive tightened up that one probably 6 or more times.

O well I've always said this ole red bucket teaches me all the time. The bolt and washer, 24$US+exchange+shipping= $82!!!!!Ca oh you should get it by spring,,,,,, £π©€!!!!

Thank goodness the piece in the crank wasn't tight!

Get reading and I guess that bolt is one time use and Ive tightened up that one probably 6 or more times.

O well I've always said this ole red bucket teaches me all the time. The bolt and washer, 24$US+exchange+shipping= $82!!!!!Ca oh you should get it by spring,,,,,, £π©€!!!!

I found by accident that brake clean is a pretty good crack detectant. I was cleaning the bore of a small engine flywheel with brake clean and when I wiped it off I could see the brake clean weeping out of the otherwise invisible crack. So if the pan is clean and dry and you spray some brake clean inside the joint. you'll see it weeping through on the outside if there are leaks. A quick check if you don't have dye penetrant.This is what I use. Having said that it might be to costly for some but I do a lot of weld repairs that are open to atmosphere and cant be pressure tested. Just repaired my oil pan on the coyote and welded oil return bungs for the turbos and spotted a pin hole on one of the welds. A must have product for me. There is nothing more aggravating than finding a slight leak in an oil pan after it is sealed on the block and full of fresh oil. You simply spray the white developer on the outside of the pan covering the weld area and then spray the red dye penetrant on the inside of the same area. the obvious pinhole or crack will appear immediately but leaving it for an hr. or so is best to reveal any cold lap in a mig weld .

https://www.vallen.ca/products/220-...t-developer-standard-12-oz-aerosol-can-cloudy

The Big M

Active Member

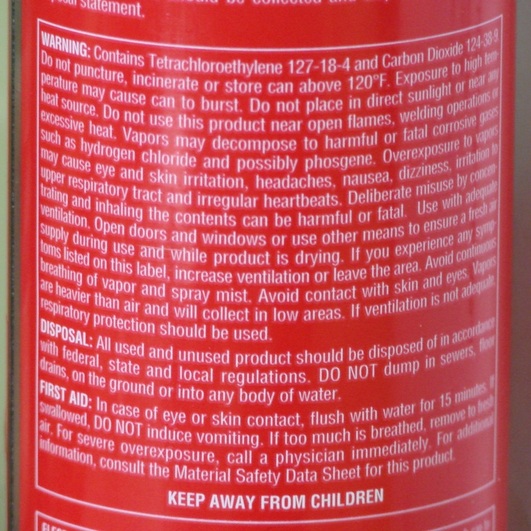

Interesting, but I’d be concerned about the risk of creating poisonous fumes if there’s any residual brake cleaner in the joint when you try to weld it up. I’m not a welder but have read there’s a risk of phosgene gas being released, and I know the welding shop at work prohibits the use of brake cleaner for that reason.

Jason: This has been discussed before, but it's worth bringing up again.Interesting, but I’d be concerned about the risk of creating poisonous fumes if there’s any residual brake cleaner in the joint when you try to weld it up. I’m not a welder but have read there’s a risk of phosgene gas being released, and I know the welding shop at work prohibits the use of brake cleaner for that reason.

You're correct, The Chlorinated Brake Kleen, plus UV light creates phosgene gas (that's the stuff they used in WW 1, NASTY!!)

Using the Non-Chlorinated version is safe, but most shops just make it verboten, because it's too easy to not pay attention to the Ingredients, and the consequences are not worth the risk........

See the article in the link below....

Safety Alert! Brake Cleaner = Phosgene Gas

Brew Bikes LLC 828-406-6668 Phone & Text. brewdude@brewracingframes.com BREW is a registered trademark and NO images or use without written consent.

www.brewracingframes.com

James