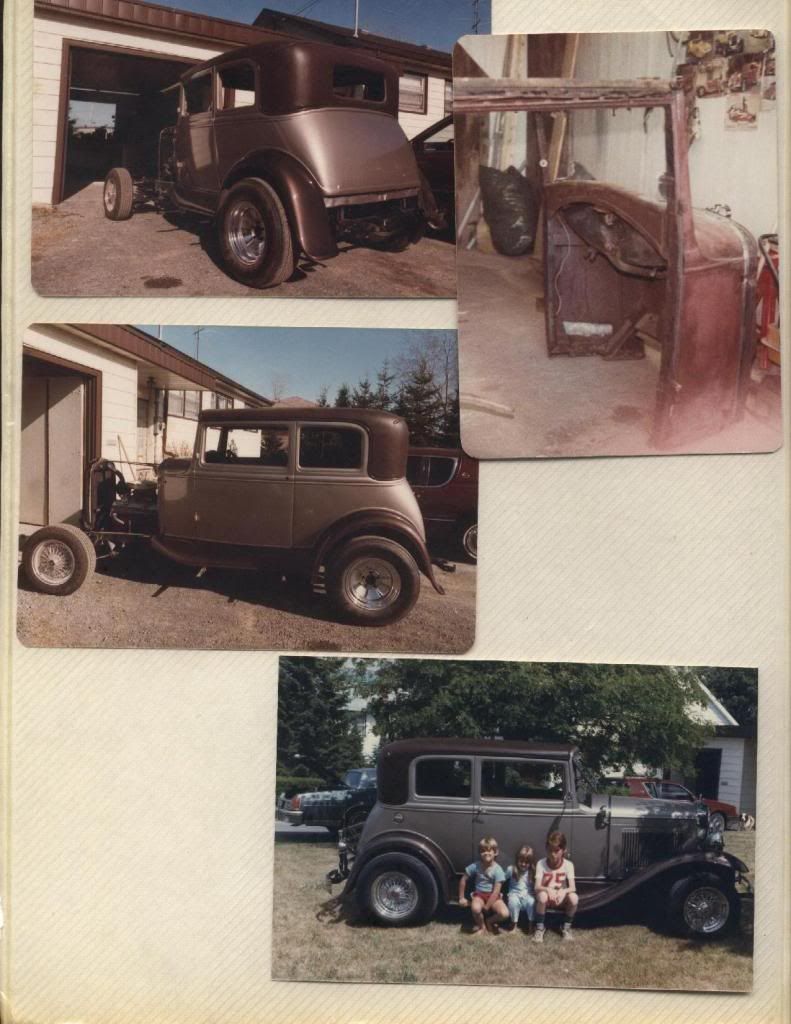

Added a link to my photo bucket pictures so that you can go through them all

Well last Friday was an eventful day as Jamie delivered the Vicky to us

Again a BIG THANKS to Jamie Rick and Daryl

Let the build begin

So far we have ( Barry and I ) squared, leveled and plumbed the H beams on the rolling table set the axle centre lines, fabed up the upper and lower side rails along with the jag mount cross member tacked together

PS when Jamie was here he taught me this picture posting stuff

http://s1137.photobucket.com/user/tooltime109/library/30 Vicky build 2011?sort=2&page=1

Well last Friday was an eventful day as Jamie delivered the Vicky to us

Again a BIG THANKS to Jamie Rick and Daryl

Let the build begin

So far we have ( Barry and I ) squared, leveled and plumbed the H beams on the rolling table set the axle centre lines, fabed up the upper and lower side rails along with the jag mount cross member tacked together

PS when Jamie was here he taught me this picture posting stuff

http://s1137.photobucket.com/user/tooltime109/library/30 Vicky build 2011?sort=2&page=1

Last edited: