Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1970 Buick Street/Strip Skylark Build

- Thread starter Twin Turbo Skylark

- Start date

Twin Turbo Skylark

Active Member

Coco and I were discussing about rear end gearing options so I thought I would continue that here.

I was saying that the new car I bought has a gearing of 5.57 in the rear end, and a 26" tall tire, and I am using a 200R4 trans which has an overdrive gear of 0.67 compared to a normal trans with a 1:1 ratio in top gear.

In general when picking a rear end ratio for drag racing purposes only I decide the max MPH that I would like to run then pick the RPM red line and then gear it so that it crosses the traps just before the red line.

These handy gear ratio or RPM calculators are something I use a lot when speccing our the rear end ratio and tire height combos:

https://www.ringpinion.com/calculators/Calc_RPM.aspx

http://www.wallaceracing.com/calcrgr.php

To start in general terms if a person had an engine like a stock Chevy 350 that had a peak HP at 4600 RPM and a peak torque at about 350 TQ at 3000 RPM and they wanted to go drag racing with a 3500 pound car the best gearing for that purpose would be roughly a 3.73 gear so that the car got off the line with some torque multiplication and did not run out of RPM on the top end of the quarter mile.

Now if the same car was hopped up with a big cam and some high flowing heads then a 4.11 rear end might be the way to go so that the engine gets up into its powerband quickly. Add the other upgrades without the extra gear and you may find it slower.

Now take 502 crate engine in the same car and you could easily get away with a 3.42 gear because the engine makes enough torque that the extra torque multiplication is not really needed and may just result in traction issues. I see lots of fast cars running 3.08 gears especially if they make mega low RPM torque.

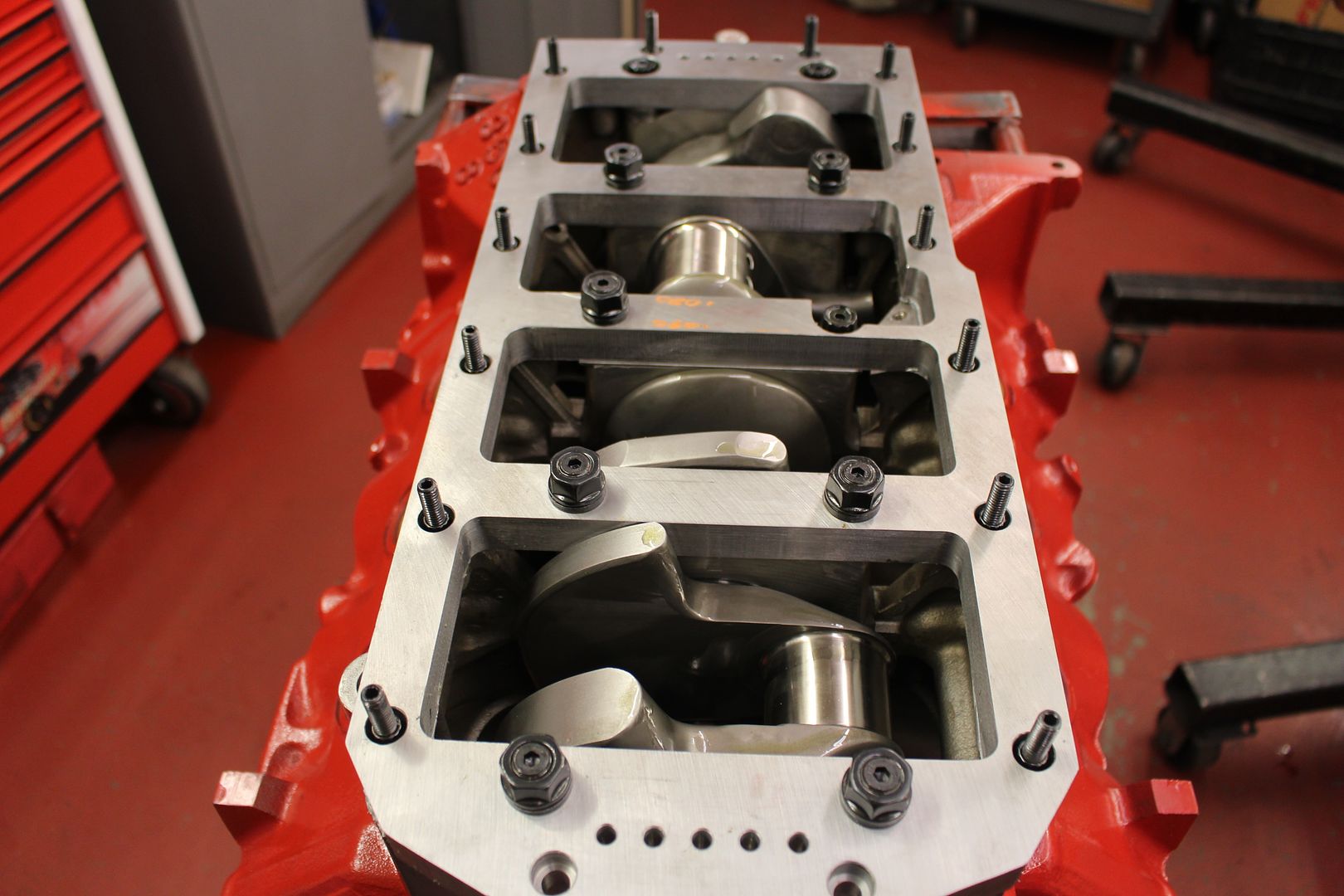

With the 77 Skylark I am building the engine will be a balanced and blueprinted Buick 350 with rods that are much stronger and lighter than stock (542 grams compared to 675 grams) and pistons that are also much lighter (555 grams compared to 700 grams) all internally balanced. The cam will have an RPM range of 3000-7300 RPM with solid lifters that are stable at high revs. The compression ratio will be matched to the cam so that the dynamic compression ratio is low enough to run on pump gas and high enough to provide maximum benefit of the cam through elevated cylinder pressures.

Being that this engine is a high revving small block with just 355 cubes you need to gear it correctly or it will be slow. If I was using a Th-400 I would go with a 4.11 gear however since I have a nice overdrive trans spare on the shelf it is a perfect match for the 5.57 gear. The stall rating of the converter (3400 RPM) matches the engine powerband and on the highway and top end of the track the converter locks up 100% so no loss in slippage. We would expect 5-8% converter slip or more on a typical non locking converter. In my case the more gear I can use the better as long as I do not run out of RPM before the traps.

So with no specific goal for ET in the quarter mile I just crunched the numbers for the 5.57 gear, overdrive trans, and it can turn 6000 RPM at 120 MPH and I will likely have only 110 MPH or something because this is not a high HP engine really. Then looking at drivability on the street and highway it will turn 3000 RPM at 65 MPH which is fine because the cam will not be too happy under load at less than than anyway. Not that this is a fuel milage car anyway but I do not think the gear will hurt the milage much if any when under 70 MPH.

My 1970 Skylark is a much different animal with the turbos it needs much less gear even with a pretty much stock Buick 350 engine internally.

That car has a 4.56 gear, 33 inch tall tires, non overdrive trans, and it's last run at the track was 10.15 in the quarter with 128 MPH but it only weighs 2980 pounds. It crosses the traps at 6000 RPM and cruises the highway at 3000 RPM. The difference is that the turbo car is powerful from idle to 6000 RPM and it likely could run just as fast in the quarter with a 4.11 gear. However I am leaving well enough alone on that one.

I was saying that the new car I bought has a gearing of 5.57 in the rear end, and a 26" tall tire, and I am using a 200R4 trans which has an overdrive gear of 0.67 compared to a normal trans with a 1:1 ratio in top gear.

In general when picking a rear end ratio for drag racing purposes only I decide the max MPH that I would like to run then pick the RPM red line and then gear it so that it crosses the traps just before the red line.

These handy gear ratio or RPM calculators are something I use a lot when speccing our the rear end ratio and tire height combos:

https://www.ringpinion.com/calculators/Calc_RPM.aspx

http://www.wallaceracing.com/calcrgr.php

To start in general terms if a person had an engine like a stock Chevy 350 that had a peak HP at 4600 RPM and a peak torque at about 350 TQ at 3000 RPM and they wanted to go drag racing with a 3500 pound car the best gearing for that purpose would be roughly a 3.73 gear so that the car got off the line with some torque multiplication and did not run out of RPM on the top end of the quarter mile.

Now if the same car was hopped up with a big cam and some high flowing heads then a 4.11 rear end might be the way to go so that the engine gets up into its powerband quickly. Add the other upgrades without the extra gear and you may find it slower.

Now take 502 crate engine in the same car and you could easily get away with a 3.42 gear because the engine makes enough torque that the extra torque multiplication is not really needed and may just result in traction issues. I see lots of fast cars running 3.08 gears especially if they make mega low RPM torque.

With the 77 Skylark I am building the engine will be a balanced and blueprinted Buick 350 with rods that are much stronger and lighter than stock (542 grams compared to 675 grams) and pistons that are also much lighter (555 grams compared to 700 grams) all internally balanced. The cam will have an RPM range of 3000-7300 RPM with solid lifters that are stable at high revs. The compression ratio will be matched to the cam so that the dynamic compression ratio is low enough to run on pump gas and high enough to provide maximum benefit of the cam through elevated cylinder pressures.

Being that this engine is a high revving small block with just 355 cubes you need to gear it correctly or it will be slow. If I was using a Th-400 I would go with a 4.11 gear however since I have a nice overdrive trans spare on the shelf it is a perfect match for the 5.57 gear. The stall rating of the converter (3400 RPM) matches the engine powerband and on the highway and top end of the track the converter locks up 100% so no loss in slippage. We would expect 5-8% converter slip or more on a typical non locking converter. In my case the more gear I can use the better as long as I do not run out of RPM before the traps.

So with no specific goal for ET in the quarter mile I just crunched the numbers for the 5.57 gear, overdrive trans, and it can turn 6000 RPM at 120 MPH and I will likely have only 110 MPH or something because this is not a high HP engine really. Then looking at drivability on the street and highway it will turn 3000 RPM at 65 MPH which is fine because the cam will not be too happy under load at less than than anyway. Not that this is a fuel milage car anyway but I do not think the gear will hurt the milage much if any when under 70 MPH.

My 1970 Skylark is a much different animal with the turbos it needs much less gear even with a pretty much stock Buick 350 engine internally.

That car has a 4.56 gear, 33 inch tall tires, non overdrive trans, and it's last run at the track was 10.15 in the quarter with 128 MPH but it only weighs 2980 pounds. It crosses the traps at 6000 RPM and cruises the highway at 3000 RPM. The difference is that the turbo car is powerful from idle to 6000 RPM and it likely could run just as fast in the quarter with a 4.11 gear. However I am leaving well enough alone on that one.

Last edited:

cocobolo

Well-Known Member

I'm getting a little confused here. The car you just got you said it had 4.88's in the back. Now you are working out the speed using 5.57's. Are we talking about two entirely different cars?

And are your tires really only 26" tall? Seems low to me, but I'm not arguing, just asking.

Maybe you can let me know how the tranny gets into overdrive while your foot is buried. Is there a switch or some sort of controller that gets you into OD?

I'll tell you a story later about the very first engine swap I ever did...it involves a Buick engine.

And are your tires really only 26" tall? Seems low to me, but I'm not arguing, just asking.

Maybe you can let me know how the tranny gets into overdrive while your foot is buried. Is there a switch or some sort of controller that gets you into OD?

I'll tell you a story later about the very first engine swap I ever did...it involves a Buick engine.

Twin Turbo Skylark

Active Member

Hi Coco,

Sorry for the confusion and I am all about learning more so please share input and stories it would be helpful.

When I bought the car the rear end was said to be a 4.88 year and then when I got it home and opened up it turned out to be a 5.57 gear. When the guy was racing he always claimed it was a 4.88 gear but holly crap did that thing leave the line with that 6.0... He's really needed less gear with that engine and therefore spun the rod bearings.

My first thought was crap I want to swap it out for a 4.11 year or something but the. When I crunched the numbers I found that I could still do 120 MPH at 6000 RPM I decided to keep the gearing at least for now.

With these 200R4 trans they will automatically shift to overdrive at full throttle in like the 700R4 that will not. This trans can just be left in drive and it shifts at 6000 RPM at full throttle or at lower RPM at less throttle. I will need to re tune the governor to get shift points higher than 6000, but that is easy. Keep in mind though this is a $4000 U.S. Trans rated for 900 Hp not a low buck stock rebuild. A stock trans would not put up with this abuse for long. Keep in mind the 200R4 trans have a dual bell housing pattern so they work with Buick, olds, Pontiac, and Chevy engines from about 1968-1999.

Speaking of cool stuff about these 200 trans here is more info as well as confirmation about the 200 being able to shift into overdrive at full throttle:

http://www.hotrod.com/articles/ccrp-0903-th-200-4r-transmission-build/

The tires are short on this car, it came with little 14 inch pizza cutters so 26" tall by 12 inch wide is about all you can fit... You can go to 29 tall by 9 inch wide but I like the look of the shorter wider tire.

Sorry for the confusion and I am all about learning more so please share input and stories it would be helpful.

When I bought the car the rear end was said to be a 4.88 year and then when I got it home and opened up it turned out to be a 5.57 gear. When the guy was racing he always claimed it was a 4.88 gear but holly crap did that thing leave the line with that 6.0... He's really needed less gear with that engine and therefore spun the rod bearings.

My first thought was crap I want to swap it out for a 4.11 year or something but the. When I crunched the numbers I found that I could still do 120 MPH at 6000 RPM I decided to keep the gearing at least for now.

With these 200R4 trans they will automatically shift to overdrive at full throttle in like the 700R4 that will not. This trans can just be left in drive and it shifts at 6000 RPM at full throttle or at lower RPM at less throttle. I will need to re tune the governor to get shift points higher than 6000, but that is easy. Keep in mind though this is a $4000 U.S. Trans rated for 900 Hp not a low buck stock rebuild. A stock trans would not put up with this abuse for long. Keep in mind the 200R4 trans have a dual bell housing pattern so they work with Buick, olds, Pontiac, and Chevy engines from about 1968-1999.

Speaking of cool stuff about these 200 trans here is more info as well as confirmation about the 200 being able to shift into overdrive at full throttle:

http://www.hotrod.com/articles/ccrp-0903-th-200-4r-transmission-build/

The tires are short on this car, it came with little 14 inch pizza cutters so 26" tall by 12 inch wide is about all you can fit... You can go to 29 tall by 9 inch wide but I like the look of the shorter wider tire.

Last edited:

cocobolo

Well-Known Member

Hey there Mr. Buick...thanks for the reply and the info.

You know, the info that often comes with these cars is often subject to questioning, the '63 Nova that my boys are working on is no exception. Similar story about the gears in that one as well. Even the engine was different than claimed.

I think the trouble was that the seller of the Nova didn't actually build the car, he just bought it, drove the can off it for 4 years and re-sold it as he bought it.

The 427 turned out to be a 454 (how sad) but the built power slide had done its' day.

I went through Art Carr's website with regard to the 200R4 - thanks for that - and I'm glad to see that good old GM made provision for that tranny to go into OD even at full throttle. Until very recently, I knew nothing to speak of about any of the GM automatics, so I'm on a steep learning curve

The high h.p.version of Art's 200R4 seems to list at $2895 US...are you getting something else done that jacks up the price?

FWIW I'm getting a 200R4 to go behind the new 383 for the Plymouth, but only a 500 h.p. version. That one is coming from Extreme Automatics in the states. They are the people who have been doing the trannys for the Buick Grand Nationals for years. Like Art Carr, they too manufacture some of their own heavy duty parts.

I ran the numbers that you have and I get the same answers...but I'm inclined to think that 3,000 on the highway is a little too high and noisy! Earmuffs maybe?

I will do you another post about the first Buick that I built and the swap that we did.

By the way, congratulations on your new addition to the family. I guess he's a hot rodder in the making!

You know, the info that often comes with these cars is often subject to questioning, the '63 Nova that my boys are working on is no exception. Similar story about the gears in that one as well. Even the engine was different than claimed.

I think the trouble was that the seller of the Nova didn't actually build the car, he just bought it, drove the can off it for 4 years and re-sold it as he bought it.

The 427 turned out to be a 454 (how sad) but the built power slide had done its' day.

I went through Art Carr's website with regard to the 200R4 - thanks for that - and I'm glad to see that good old GM made provision for that tranny to go into OD even at full throttle. Until very recently, I knew nothing to speak of about any of the GM automatics, so I'm on a steep learning curve

The high h.p.version of Art's 200R4 seems to list at $2895 US...are you getting something else done that jacks up the price?

FWIW I'm getting a 200R4 to go behind the new 383 for the Plymouth, but only a 500 h.p. version. That one is coming from Extreme Automatics in the states. They are the people who have been doing the trannys for the Buick Grand Nationals for years. Like Art Carr, they too manufacture some of their own heavy duty parts.

I ran the numbers that you have and I get the same answers...but I'm inclined to think that 3,000 on the highway is a little too high and noisy! Earmuffs maybe?

I will do you another post about the first Buick that I built and the swap that we did.

By the way, congratulations on your new addition to the family. I guess he's a hot rodder in the making!

cocobolo

Well-Known Member

Long before you were a gleam in your dad's eye, I had a '55 Chevy 4 door sedan, 210 model. It came with the trusty old Blue Flame 6 banger and three on the tree. To say it was a mundane performer is putting it mildly.

Well, one day I was down at Payless Auto on Hastings street in Burnaby getting an exhaust cutout put on (Woo Hoo!).

A gorgeous '56 Chevy pulled out of their shop and took off up the street at WOT. It was the first time I had seen one of these things go, and was I ever impressed.

So I asked the mechanic at Payless what was in the Chevy. It was a 283 with very little done to it. Mild cam and four barrel and dual exhaust.

To cut the story short I started asking questions about engine swaps, different motors and so on, and I ended up finding a 322 c.i. Buick engine out of a '56 Roadmaster. It had a Ford 11" truck clutch assembly which in turn was bolted to a 3 speed Packard transmission. I don't remember what I paid for it, but it must have been cheap.

So I took the whole engine apart...this was a time when all I had pulled apart before was a 239 Flathead.

I had my old friend Mr. Swenson - never did know his first name - bore the block out .125". Shows you how little I knew about motors. I got some Jahns 11- 1 pistons from Cal Van on Kingsway. For the valve train I had Jack Shadbolt grind an Isky E2R cam, his store then was down on Broadway, just 2 blocks from where I lived. This was a solid lifter cam, so since adjustable rockers were not available, I found some Gotha adjustable pushrods. Not much in the way of choices back in the day.

I had to stay with the stock intake manifold but bolted on a '64 Corvette carb. To do that I had to grind out the bores on the manifold and drill new mounting holes. That's a story all by itself.

So the old 6 banger came out of the '55, and then Cliff (30 Chev on this site I think) helped me to do the actual swap. Of course there was some cutting and fabricating to do, but I already had a set of torches by then. I think this was either 1963 or possibly 1964.

We eventually got the thing running, and I couldn't believe how much torque this thing had. I used to drive down 16th avenue towards UBC heading up a steep hill. I would put the car in high gear at 800 rpm and floor it. It would go up that hill like it was a flat road, incredible.

Eventually sold the car and ordered a brand new '65 Chevelle from Dueck on Broadway. The only options were 327, Muncie 4 speed, radio and backup lights, which were a $10 option.

Well, one day I was down at Payless Auto on Hastings street in Burnaby getting an exhaust cutout put on (Woo Hoo!).

A gorgeous '56 Chevy pulled out of their shop and took off up the street at WOT. It was the first time I had seen one of these things go, and was I ever impressed.

So I asked the mechanic at Payless what was in the Chevy. It was a 283 with very little done to it. Mild cam and four barrel and dual exhaust.

To cut the story short I started asking questions about engine swaps, different motors and so on, and I ended up finding a 322 c.i. Buick engine out of a '56 Roadmaster. It had a Ford 11" truck clutch assembly which in turn was bolted to a 3 speed Packard transmission. I don't remember what I paid for it, but it must have been cheap.

So I took the whole engine apart...this was a time when all I had pulled apart before was a 239 Flathead.

I had my old friend Mr. Swenson - never did know his first name - bore the block out .125". Shows you how little I knew about motors. I got some Jahns 11- 1 pistons from Cal Van on Kingsway. For the valve train I had Jack Shadbolt grind an Isky E2R cam, his store then was down on Broadway, just 2 blocks from where I lived. This was a solid lifter cam, so since adjustable rockers were not available, I found some Gotha adjustable pushrods. Not much in the way of choices back in the day.

I had to stay with the stock intake manifold but bolted on a '64 Corvette carb. To do that I had to grind out the bores on the manifold and drill new mounting holes. That's a story all by itself.

So the old 6 banger came out of the '55, and then Cliff (30 Chev on this site I think) helped me to do the actual swap. Of course there was some cutting and fabricating to do, but I already had a set of torches by then. I think this was either 1963 or possibly 1964.

We eventually got the thing running, and I couldn't believe how much torque this thing had. I used to drive down 16th avenue towards UBC heading up a steep hill. I would put the car in high gear at 800 rpm and floor it. It would go up that hill like it was a flat road, incredible.

Eventually sold the car and ordered a brand new '65 Chevelle from Dueck on Broadway. The only options were 327, Muncie 4 speed, radio and backup lights, which were a $10 option.

Twin Turbo Skylark

Active Member

Wow Coco thanks for all the cool stories I really do envy you guys who grew up around these old cars when they were commonly used. I really value the experience that you and other hot rod guys pas onto to use young guys!

When I looked into having a 2004R done to handle big power I found that CK Performance has something different than many other companies and that is that they use more billet parts instead of heat treating stock parts. This is the trans I got below however with some more upgrades:

"CK Performance STAGE 2 2004R TRANSMISSION

THE STAGE 2 2004R IS BUILT FOR ENGINES PRODUCING UP TO 800 FOOT POUNDS OF TORQUE. EACH TRANSMISSION IS PROFESSIONALLY ASSEMBLED AND THEN GIVEN A THOROUGH ROAD TEST IN OUR TEST VEHICLE TO GUARANTEE FLAWLESS OPERATION PRIOR TO SHIPPING.

COMPETITION COMPONENTS

E4340 STEEL BILLET SHAFT FORWARD CLUTCH DRUM.E4340 STEEL BILLET INPUT SHAFT.E4340 STEEL BILLET OVERDRIVE PLANETARY CARRIER ASSEMBLY.E4340 STEEL BILLET OVERDRIVE RING GEAR .HEAT TREATED STATOR TUBE.HEAT TREATED SUN GEAR SHELL.OVERSIZE BILLET ALUMINUM SERVO ASSEMBLY.ROLLERIZED OVERDRIVE RING GEAR,CENTER SUPPORT,DIRECT DRUM,FORWARD DRUM,SUN GEAR SHELL,LO REVERSE CLUTCH HOUSINGAND REAR INTERNAL GEAR. THESE BEARINGS REDUCE INTERNAL FRICTION AND HORSEPOWER LOSS CREATED AND CONSUMED DURING NORMAL INTERNAL COMPONENT ROTATION.THEY ALSO INCREASE THE THRUST SURFACE AREAS BETWEEN ROTATING INTERNAL COMPONMENTS

CLUTCH AND BAND UPGRADES

OVERSIZED ALTO RED LINED 2ND GEAR BAND. CUSTOM DIRECT CLUTCH PACK WITH 6 ALTO RED LINED FRICTIONS AND 6 OVERSIZE STEEL PLATES. UPDATED OVERDRIVE CLUTCH PACK WITH 3 BORG WARNER TAN FRICTIONS. CUSTOM CNC MACHINED BILLET ALUMINUM DIRECT CLUTCH PISTON .

HYDRAULIC UPGRADES

ALL BUILDS START WITH A BRAND NEW GENERAL MOTORS FRONT PUMP ASSEMBLY.THE PUMP IS THEN REWORKED AND ASSEMBLED WITH STEEL VANE RINGS,DUAL HIGH RATE PUMP SLIDE PRIMING SPRINGS,A NEW HEAVY DUTY PRESSURE REGULATOR SPRING ,AND OVERSIZED CNC MACHINED TV AND INTERMEDIATE BOOST VALVES.THESE MODIFICATIONS IMPROVE AND INCREASE LINE AND LUBRICTION PRESSURES. ADDITIONAL PASSAGES ARE ADDED TO THE CENTER SUPPORT FOR IMPROVED THRUST SURFACE LUBRICATION. "

When I looked into having a 2004R done to handle big power I found that CK Performance has something different than many other companies and that is that they use more billet parts instead of heat treating stock parts. This is the trans I got below however with some more upgrades:

"CK Performance STAGE 2 2004R TRANSMISSION

THE STAGE 2 2004R IS BUILT FOR ENGINES PRODUCING UP TO 800 FOOT POUNDS OF TORQUE. EACH TRANSMISSION IS PROFESSIONALLY ASSEMBLED AND THEN GIVEN A THOROUGH ROAD TEST IN OUR TEST VEHICLE TO GUARANTEE FLAWLESS OPERATION PRIOR TO SHIPPING.

COMPETITION COMPONENTS

E4340 STEEL BILLET SHAFT FORWARD CLUTCH DRUM.E4340 STEEL BILLET INPUT SHAFT.E4340 STEEL BILLET OVERDRIVE PLANETARY CARRIER ASSEMBLY.E4340 STEEL BILLET OVERDRIVE RING GEAR .HEAT TREATED STATOR TUBE.HEAT TREATED SUN GEAR SHELL.OVERSIZE BILLET ALUMINUM SERVO ASSEMBLY.ROLLERIZED OVERDRIVE RING GEAR,CENTER SUPPORT,DIRECT DRUM,FORWARD DRUM,SUN GEAR SHELL,LO REVERSE CLUTCH HOUSINGAND REAR INTERNAL GEAR. THESE BEARINGS REDUCE INTERNAL FRICTION AND HORSEPOWER LOSS CREATED AND CONSUMED DURING NORMAL INTERNAL COMPONENT ROTATION.THEY ALSO INCREASE THE THRUST SURFACE AREAS BETWEEN ROTATING INTERNAL COMPONMENTS

CLUTCH AND BAND UPGRADES

OVERSIZED ALTO RED LINED 2ND GEAR BAND. CUSTOM DIRECT CLUTCH PACK WITH 6 ALTO RED LINED FRICTIONS AND 6 OVERSIZE STEEL PLATES. UPDATED OVERDRIVE CLUTCH PACK WITH 3 BORG WARNER TAN FRICTIONS. CUSTOM CNC MACHINED BILLET ALUMINUM DIRECT CLUTCH PISTON .

HYDRAULIC UPGRADES

ALL BUILDS START WITH A BRAND NEW GENERAL MOTORS FRONT PUMP ASSEMBLY.THE PUMP IS THEN REWORKED AND ASSEMBLED WITH STEEL VANE RINGS,DUAL HIGH RATE PUMP SLIDE PRIMING SPRINGS,A NEW HEAVY DUTY PRESSURE REGULATOR SPRING ,AND OVERSIZED CNC MACHINED TV AND INTERMEDIATE BOOST VALVES.THESE MODIFICATIONS IMPROVE AND INCREASE LINE AND LUBRICTION PRESSURES. ADDITIONAL PASSAGES ARE ADDED TO THE CENTER SUPPORT FOR IMPROVED THRUST SURFACE LUBRICATION. "

I had my old friend Mr. Swenson - never did know his first name - bore the block out .125". Shows you how little I knew about motors. I got some Jahns 11- 1 pistons from Cal Van on Kingsway. For the valve train I had Jack Shadbolt grind an Isky E2R cam, his store then was down on Broadway, just 2 blocks from where I lived. This was a solid lifter cam, so since adjustable rockers were not available, I found some Gotha adjustable pushrods. Not much in the way of choices back in the day.

I had to stay with the stock intake manifold but bolted on a '64 Corvette carb. To do that I had to grind out the bores on the manifold and drill new mounting holes. That's a story all by itself.

So the old 6 banger came out of the '55, and then Cliff (30 Chev on this site I think) helped me to do the actual swap. Of course there was some cutting and fabricating to do, but I already had a set of torches by then. I think this was either 1963 or possibly 1964.

We eventually got the thing running, and I couldn't believe how much torque this thing had. I used to drive down 16th avenue towards UBC heading up a steep hill. I would put the car in high gear at 800 rpm and floor it. It would go up that hill like it was a flat road, incredible.

Eventually sold the car and ordered a brand new '65 Chevelle from Dueck on Broadway. The only options were 327, Muncie 4 speed, radio and backup lights, which were a $10 option.

Coco, your story brings back several memories. Thanks. Yeah 16th hill up to Dunbar was a test we used often. With the average cars we drove then, if you got a good run at it you might make it up without grabbing 2nd. I don't remember your '55, but it sounds like it would have been a real sleeper. I'm sure I did meet you with the Chevelle at Kings Burgers on Kingsway shortly after you got it, and thinking it too was a great unsuspecting sleeper. I couldn't afford a new car, but dreamed about a new 327 Nova post, like Grumpy Jenkins', so settled for a '62 Acadian in which I swapped a 283 with a Corvette AFB intake and a Duntov cam & solids. That cam was the first time I hadn't gone to Roy Shadbolt for a regrind. It seemed Shadbolt's favourite specs were 3/4 race Ford intakes with Chrysler exhausts. When Roy moved from his Broadway shop, he bought my Dad's shop on 5th Ave. The sleepers were so much fun, especially if you could beat the muscle cars that the rich kids were talking their mothers into buying.

cocobolo

Well-Known Member

That's funny.Coco, your story brings back several memories. Thanks. Yeah 16th hill up to Dunbar was a test we used often. With the average cars we drove then, if you got a good run at it you might make it up without grabbing 2nd. I don't remember your '55, but it sounds like it would have been a real sleeper. I'm sure I did meet you with the Chevelle at Kings Burgers on Kingsway shortly after you got it, and thinking it too was a great unsuspecting sleeper. I couldn't afford a new car, but dreamed about a new 327 Nova post, like Grumpy Jenkins', so settled for a '62 Acadian in which I swapped a 283 with a Corvette AFB intake and a Duntov cam & solids. That cam was the first time I hadn't gone to Roy Shadbolt for a regrind. It seemed Shadbolt's favourite specs were 3/4 race Ford intakes with Chrysler exhausts. When Roy moved from his Broadway shop, he bought my Dad's shop on 5th Ave. The sleepers were so much fun, especially if you could beat the muscle cars that the rich kids were talking their mothers into buying.

When I took the 6 out and put the Buick in, the '55 was hand painted - by brush - in the finest Tremco off-red undercoat colour. Remember that stuff? I think it was about six bucks a can back then.

Why did I say Jack Shadbolt...? Must be confusing him with Jack Williams, who did the driveshaft for the '55. When the Buick was done, it ended up with 344 c.i. which was a fairly big motor back in the day. It moved the '55 right along.

Something else I did in my total ignorance was to grind away the back side of all the valves on my grinder. I bet they were well balanced! But the Buick would go over 6,000 with a lightened valve train and beefier springs.

Just got an email from Cliff, same Cliff who helped me with the swap. Seems he is visiting the area just down at Lee Creek...gonna see if we can hook up either late tomorrow or the next day.

Yes, I'm sure we would have met at Kings...that was my home away from home.

Why did I say Jack Shadbolt...? Must be confusing him with Jack Williams, who did the driveshaft for the '55.

An easy mistake. Actually Jack Shadbolt was Roy's brother. Jack is the renound Canadian painter.

cocobolo

Well-Known Member

An easy mistake. Actually Jack Shadbolt was Roy's brother. Jack is the renound Canadian painter.

Seems to me that I have been corrected on that before.

Thank goodness it's the memory that's the first thing to go!

cocobolo

Well-Known Member

OK, back to another Buick story.

In about '89 or so I built a T-bucket from scratch. I intended to use a 400" Buick and tranny out of my Buick wagon. But unfortunately I managed to seriously overheat the engine and ruined it.

Ended up finding a stock 455 with 7.87 compression. This was by actual measurement. Bolted that to the turbo 400 and dropped it into the T.

3.42 gears in the back, and my driveshaft was 11" long from the centre of one u-joint to the next. Hardly even had room to fit a driveshaft loop in place.

Took it to the old car drags in '91 and ran 11.47 @ 122, but couldn't get it out of the hole to save my life. Fun car.

In about '89 or so I built a T-bucket from scratch. I intended to use a 400" Buick and tranny out of my Buick wagon. But unfortunately I managed to seriously overheat the engine and ruined it.

Ended up finding a stock 455 with 7.87 compression. This was by actual measurement. Bolted that to the turbo 400 and dropped it into the T.

3.42 gears in the back, and my driveshaft was 11" long from the centre of one u-joint to the next. Hardly even had room to fit a driveshaft loop in place.

Took it to the old car drags in '91 and ran 11.47 @ 122, but couldn't get it out of the hole to save my life. Fun car.

Twin Turbo Skylark

Active Member

OK, back to another Buick story.

In about '89 or so I built a T-bucket from scratch. I intended to use a 400" Buick and tranny out of my Buick wagon. But unfortunately I managed to seriously overheat the engine and ruined it.

Ended up finding a stock 455 with 7.87 compression. This was by actual measurement. Bolted that to the turbo 400 and dropped it into the T.

3.42 gears in the back, and my driveshaft was 11" long from the centre of one u-joint to the next. Hardly even had room to fit a driveshaft loop in place.

Took it to the old car drags in '91 and ran 11.47 @ 122, but couldn't get it out of the hole to save my life. Fun car.

That must have been a lot of fun! All it needed was a turbocharger and a 2.56 gear and it would have been a real death trap LOL!

Twin Turbo Skylark

Active Member

I have been busy collecting cool stuff for low $! Found this GMC 3500 for $300 running and driving! Had a TBI 350 and TH-400 with 4.11 ratio 14 bolt axle:

$900 for this 2001 GMC 1500 HD with 6.0,4L80E, no rust, 4.11 gears:

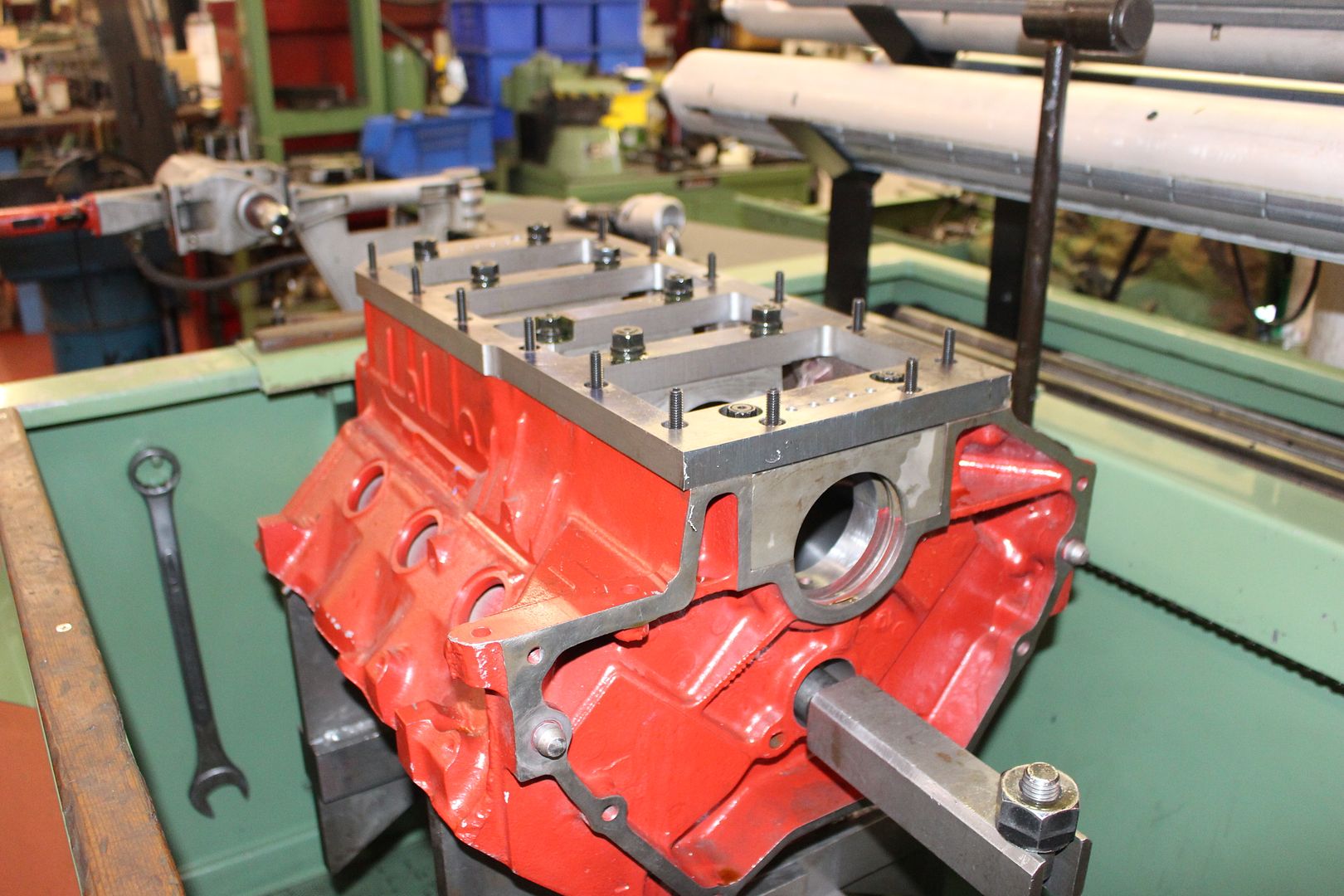

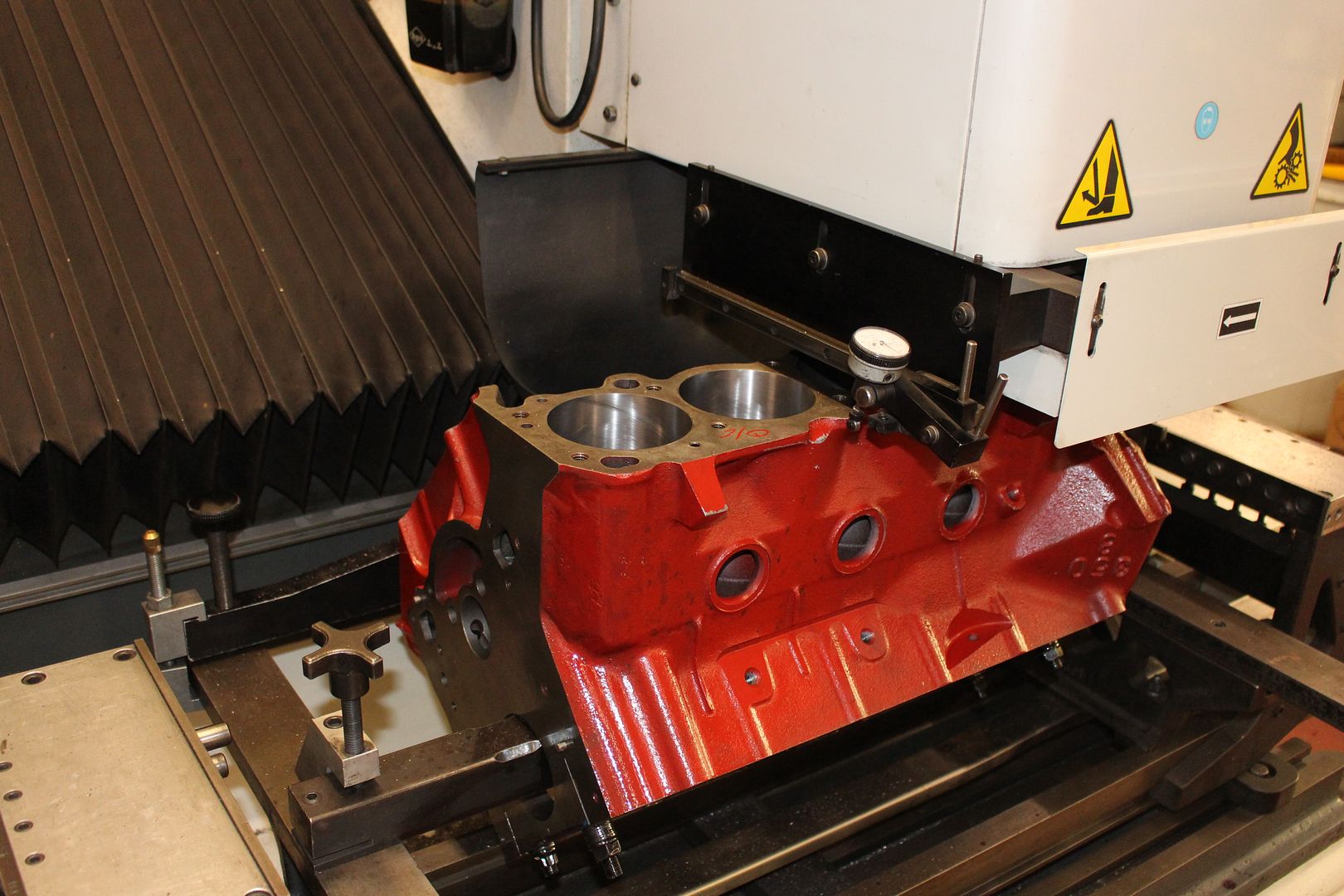

Got the custom oil pan made for the Buick:

Got two exhaust temp. probes and a kit so I can monitor the temperatures in the exhausts of the turbo buick engine:

Dragged home a shed to fit more engines in!

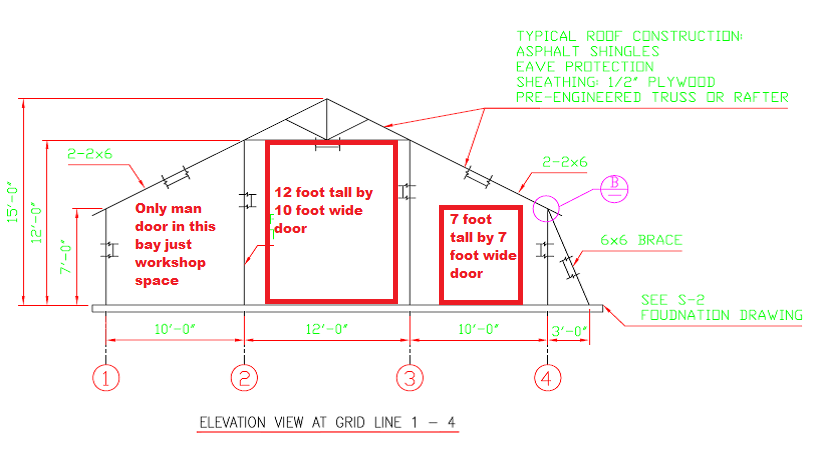

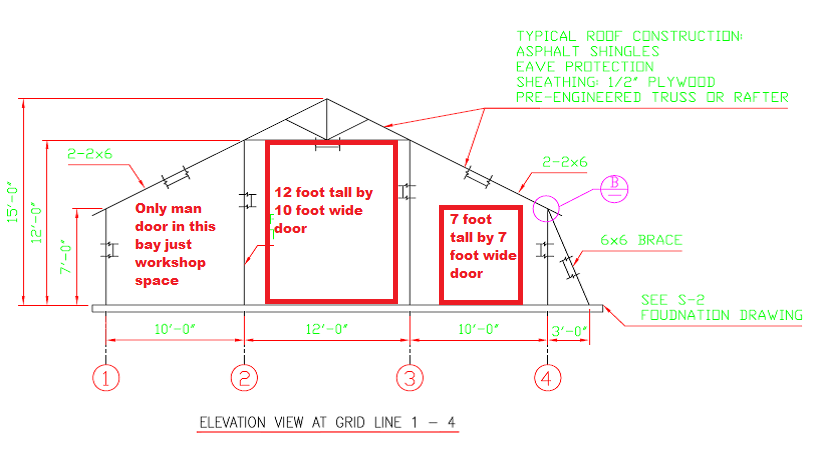

Planned out a garage build and had an engineer stamp it, notice the tall center bay for a 4 post lift:

Found this old vintage saw for $100 going to use it to help build the garage.... Will be handy to notch the 6x6 posts to fit the 2X12s.

Lastly found this cool truck! Solid 1 ton axles swapped into this one, plus a roll cage, and lots of cool stuff. No engine, no trans, $700:

While waiting for the alum heads I am keeping busy! Sold the two transfer cases that came with the truck for more than I paid for the truck.

This 1990 gmc came with independent suspension but for real off road abuse you want some solid axles... Tons of work went into this and it's really well done.

Pulled it up onto the flat deck for safe keeping, love that PTO winch:

$900 for this 2001 GMC 1500 HD with 6.0,4L80E, no rust, 4.11 gears:

Got the custom oil pan made for the Buick:

Got two exhaust temp. probes and a kit so I can monitor the temperatures in the exhausts of the turbo buick engine:

Dragged home a shed to fit more engines in!

Planned out a garage build and had an engineer stamp it, notice the tall center bay for a 4 post lift:

Found this old vintage saw for $100 going to use it to help build the garage.... Will be handy to notch the 6x6 posts to fit the 2X12s.

Lastly found this cool truck! Solid 1 ton axles swapped into this one, plus a roll cage, and lots of cool stuff. No engine, no trans, $700:

While waiting for the alum heads I am keeping busy! Sold the two transfer cases that came with the truck for more than I paid for the truck.

This 1990 gmc came with independent suspension but for real off road abuse you want some solid axles... Tons of work went into this and it's really well done.

Pulled it up onto the flat deck for safe keeping, love that PTO winch:

Twin Turbo Skylark

Active Member

First of all where are ya going to put all this stuff ???/ Obviously you live in a residential subdivision. I thought at one time you were planning a move to BC.....has that been shelved?

Awesome looking oil pan by the way !

I may move back to BC but not till I retire.... Only 34 now so many years to go.

No problem with space I have the house 10 minutes away from Edmonton, 4 acres a ways in the country, and a house 15 minutes from there with 4 lots and alley access down the back with full road frontage along all 4 lots.

The 4 acres:

https://www.youtube.com/watch?v=WkuhLpJ3Voo&app=desktop

And the little house... Have a good renter with a BIG dog and I keep the yard and the sheds for my use and storage:

Twin Turbo Skylark

Active Member

I'm intrigued to see the shop come together. Is that a 12' ceiling height or door opening?

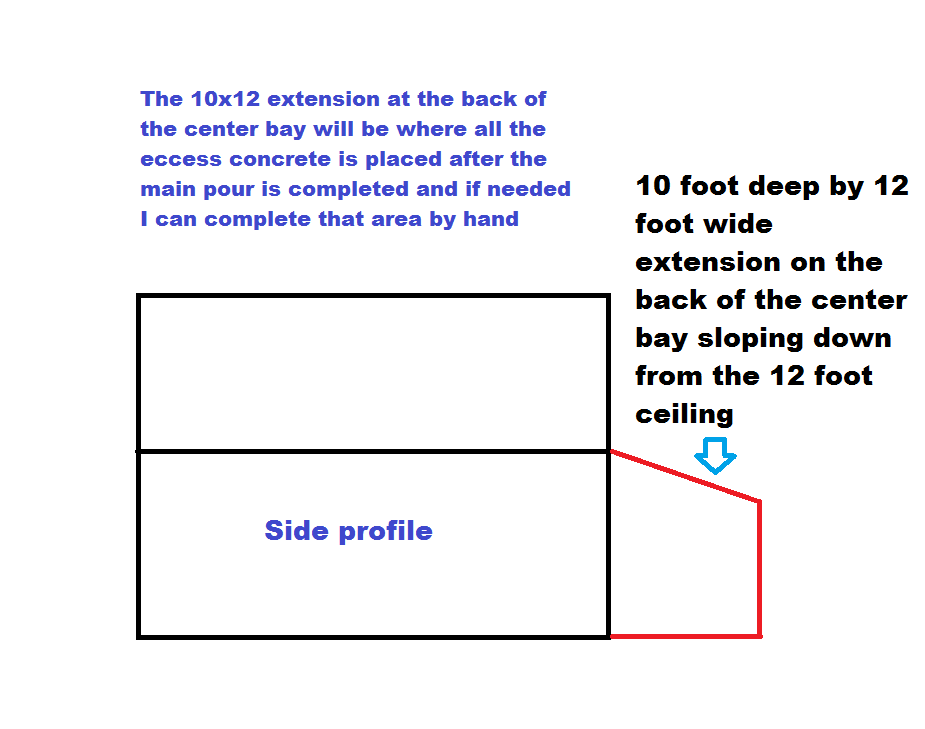

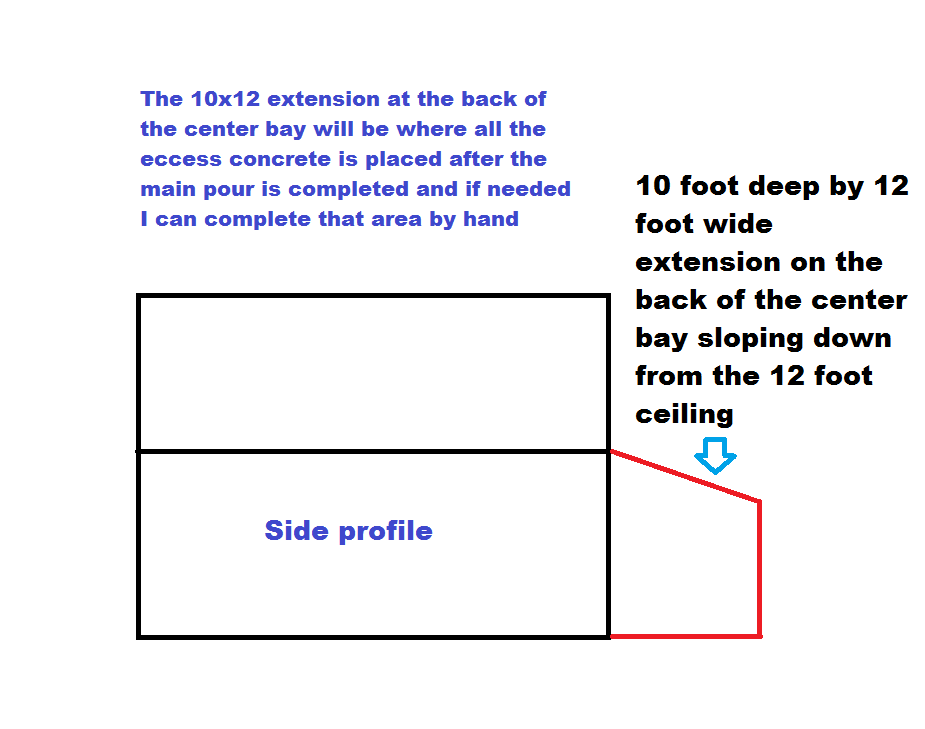

Thanks for the interest. It took a long time for me to come up with the design but it came together perfectly once I found the right engineer to make my plan official! The Center 12 feet of the shop will have a 12 foot cieling and 12 foot roll up door so it does not impede the height. The shop is built off 16 6x6 uprights so there will be 4 uprights in the shop. 2 uprights on each side of the 12 foot wide bay but I can work around them. 32 feet wide, 26 feet deep plus a 10 foot extension at the back. Not huge but will work well. There are several reasons for my design.

1. This is a low budget build

2. I wanted max space for the $ with conventional wood from the store no engineered or super long materials

3. Center bay needed to be tall enough for a lift

4. One side bay for car storage

5. Other side bay for workshop and engine building

6. I needed it so that in the first phase I could pour the pad and setup a carport with just the uprights and the roof but not enclosed. Then as I have time and $ I can frame in the walls but the design is structurally sound even without the walls. The engineer setup the knee brace at the side so that we could eliminate a ton of triangulation on the rest of the building to keep the clearance for tall vehicles and simplify the construction which I'm doing myself... The small 12 foot engineered trusses will fit on my trailer and then 2x6 for the side bay roofs...

I like the nice low roof on the sides it will make it easy to sheet in, then spray foam insulation, electrical, more insulation then OSB interior. Nothing fancy but low cost and functional... And because a garage is never big enough I am adding an extension on the back of the 12 foot tall bay 10 feet deep... Also putting my 16 foot cube from my cube van beside the shop for engine storage.

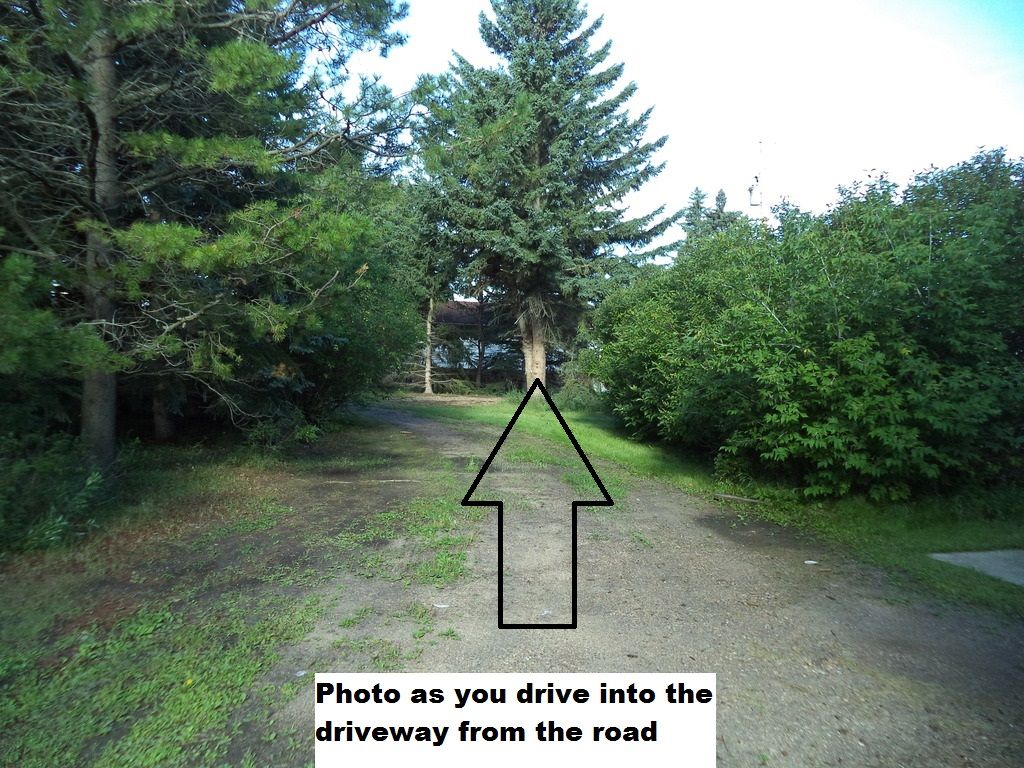

A few random photos of the yard and little house...

The house sits in the center of 4 50X125 foot lots, and has road access down the front and alley access down the back of all 4 lots. Conveniently there is a nice driveway trough from the road to the alley which is handy!

The trees are TALL!

Nothing special for a house but it is on 4 lots and it is only 10 minutes drive away from the Acreage that I posted pics of above..

Spare lot where I will build the garage:

Last edited:

The Big M

Active Member

Sounds like a nice setup! A depth of 26' is decent, especially with the extra bumpout at the end of the 12' bay and a dedicated workshop bay. I'm at 18x26 on my detached and the only reason it's still functional for tool and car storage is the extra depth.

The roll-up door makes sense. I was thinking you were doing a standard sectional door and was curious how that was going to work. My garage was built by the previous owner of the house and I ran into issues trying to add an opener due to the way he installed the 9' door into the 10' ceiling height. I ended up going with a jackshaft-style opener which I really like but it was a bit of a process to make it fit.

I was thinking you were doing a standard sectional door and was curious how that was going to work. My garage was built by the previous owner of the house and I ran into issues trying to add an opener due to the way he installed the 9' door into the 10' ceiling height. I ended up going with a jackshaft-style opener which I really like but it was a bit of a process to make it fit.

The roll-up door makes sense.