Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1950 Mercury custom build

- Thread starter K13

- Start date

So is that the top of the door we see?…window openings filled in?…or am I looking at it wrong?…..

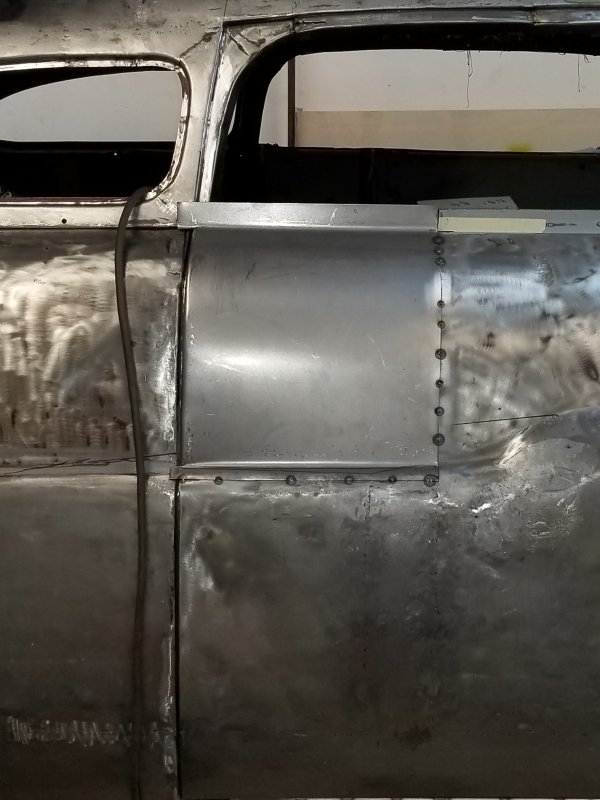

Yes top of the door. Originally this car was set up to have a Gene Winfield Fiberglass Carson top and the door tops were just sealed up (poorly like everything else) to run it like a roadster. I haven't finished cutting it out on this side of the car yet. I am going to have to rebuild the door tops to accommodate glass.So is that the top of the door we see?…window openings filled in?…or am I looking at it wrong?…..

Wow..that’s dedication …think I would have found another door …but then again I don’t have your skills..or patience…good stuff..carry on…

Well still plugging along on this mess.

I finished fitting the last patch for the door and tacked it in. It was tedious as the inner frame of the door didn't match the quarter panel shape so that had to be modified before I could fit the patch panel.

Big hole

Patch tacked in place.

I

And I started fitting the window frame. All I have at the tops from a 4 door to work with so I am going to have to make a lot of the top frame from scratch.

I finished fitting the last patch for the door and tacked it in. It was tedious as the inner frame of the door didn't match the quarter panel shape so that had to be modified before I could fit the patch panel.

Big hole

Patch tacked in place.

I

And I started fitting the window frame. All I have at the tops from a 4 door to work with so I am going to have to make a lot of the top frame from scratch.

John in Oz

Well-Known Member

I haven't been on here for a while really to keep up with what has been happening here, so I went through your thread. Man alive you have been doing a brilliant job here, very nice work to. I don't think I'd live long enough to take on a project like this. Brilliant and thanks for your thread.

John in Oz

Well-Known Member

Niether have I mate, I don't know if I can put a DVD into the TV I have now, Give me enthusiasm to get back onto the PontiacI should have added that John in Oz is actually a Kiwi.

Well I am enjoying the process so much I am doing everything twice.

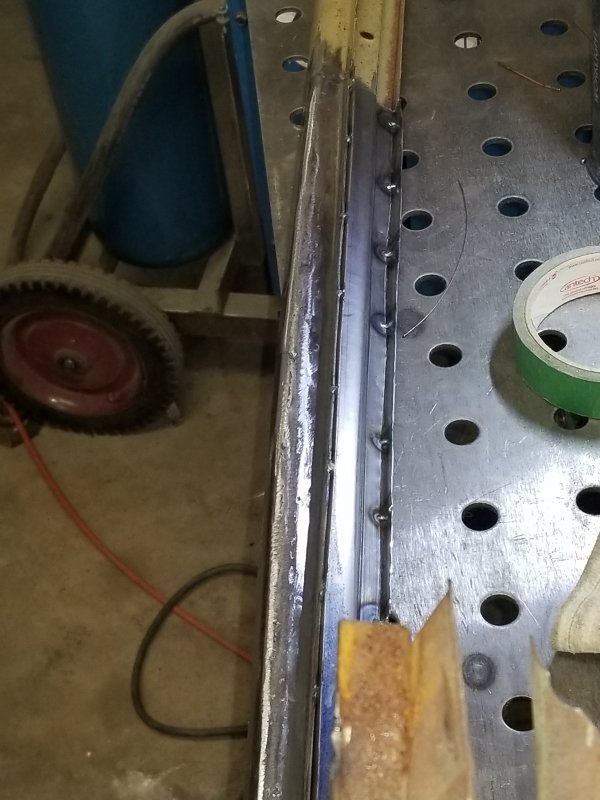

Because the window frames I have are actually the rear door frames from a 4 door I have to make a pretty long section to bridge between the pieces I have. Not really thinking I went ahead a built a section out of the 18 Gauge I hade laying around. well when I got it done it weighed a ton compared to the other pieces so I am going to remake it in 20 gauge.

It is basically 3 pieces that make up the frame so that was the first job bending those up. I had to make a bead roller die in the process as well so that delayed me while I waited for the steel place to get the size round bar I need in.

Here are the pieces:

This is the one I need to die for the right hand side jog.

This is what they look like assembled. This is the 18 Gauge the above is all the pieces I have remade in 20.

And all the pieces for the complete frame. Now I just have to assemble the new one.

Because the window frames I have are actually the rear door frames from a 4 door I have to make a pretty long section to bridge between the pieces I have. Not really thinking I went ahead a built a section out of the 18 Gauge I hade laying around. well when I got it done it weighed a ton compared to the other pieces so I am going to remake it in 20 gauge.

It is basically 3 pieces that make up the frame so that was the first job bending those up. I had to make a bead roller die in the process as well so that delayed me while I waited for the steel place to get the size round bar I need in.

Here are the pieces:

This is the one I need to die for the right hand side jog.

This is what they look like assembled. This is the 18 Gauge the above is all the pieces I have remade in 20.

And all the pieces for the complete frame. Now I just have to assemble the new one.

Thanks.

Well I got the top piece remade in 20 G which made it much lighter so I fit the three piece together to make the top and tacked them together. Then I decided on the lower window frame section I am going to blend it into the top of the door as the belt line is still not straight so I made that a complete piece as well and this is where I stand. All of this has led me to discover that the roof line above the door is all over the place in both directions so that will be needing to be fixed as well. Sigh Not a lot of fun when you literally have nothing original to baseline off of.

Well I got the top piece remade in 20 G which made it much lighter so I fit the three piece together to make the top and tacked them together. Then I decided on the lower window frame section I am going to blend it into the top of the door as the belt line is still not straight so I made that a complete piece as well and this is where I stand. All of this has led me to discover that the roof line above the door is all over the place in both directions so that will be needing to be fixed as well. Sigh Not a lot of fun when you literally have nothing original to baseline off of.

Ok so the frames are not a straight line on the front face from front to back on these cars so I had to do some modifications to get the correct shape in them. I didn't really have another way to easily do it so I had to cut it add a filler and weld it back together. Then I had to hammer out the top edge to get a curve in it. It still needs a bit of tweaking but it is way better than it was. I had to do the same to the lower piece but forgot to take pictures.

John in Oz

Well-Known Member

That is a big effort you are putting in there, that car looks great already.

Been awhile but I was not happy with the direction the door tops were going so needed to wrap my head around what I was going to do to fix them. The solution? Start over again. This time I used a tipping wheel to do the bends so they were not straight lines or shrunk and stretched the edges to get the flow I needed. Much happier with the results.