Already have the wheels. Stay tuned, they will show up in subsequent postsGlad you are keeping the side mounts. What are plans for wheels?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1931 Deluxe Delivery renovations.

- Thread starter licensed to kill

- Start date

And I thought that you were a magician, being able to do all this stuff at lightning speed

LOL, Nothing could be further from the truth. I'm into this project for three years now and have not accomplished much considering that I have all winter to work on it. Of course this is the first time I've tackled a project of this magnitude and I am "self taught" which means i learned from someone that doesn't know what they are doing. The only exception is when i got to working the sheet metal where I took a crash course with JVO which was a HUGE help without which I would never finish this project.And I thought that you were a magician, being able to do all this stuff at lightning speed

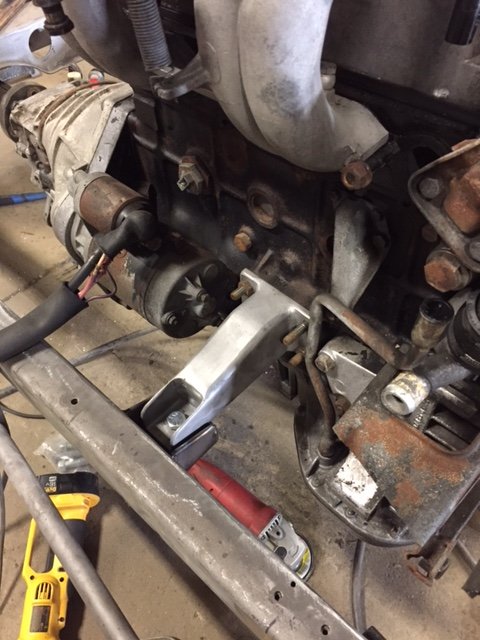

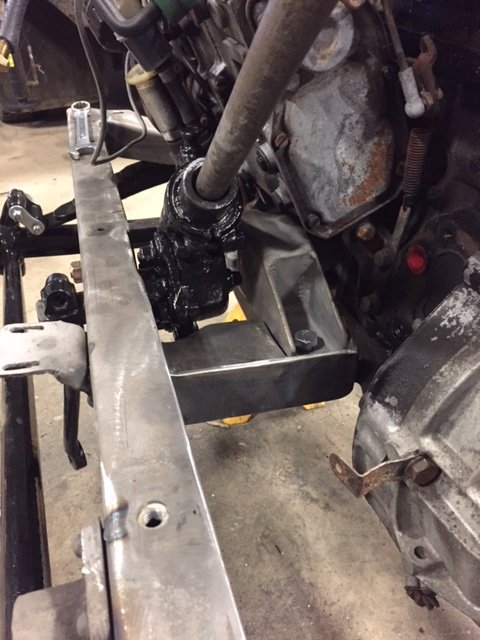

Motor mounts made. The engine had nice 4 bolt square pads that are vertical for the mounts making it easier to make mounts for it. One problem with my mount on the drivers side is that in order to remove the steering box, I have to pull the engine. I may replace the motor mount studs with bolts so I could pull the mount to make clearance for steering box removal (should it become necessary) rather than pulling the engine.

Last edited:

Installing the front axle and setting the caster. For some unknown reason I didn't take any pics of the install of the triangulated 4 link or any progressive pics of the frame mods in the back but looking a these pics, I did that before doing the front axle.

Yes, there nothing unique about this. It's pretty standard stuff with most taken from the 2 hot rodded model A's that I already have that were done this way when I got them. The only "unique" thing about it is that it is all a first for me. I bit off more than I can chew on this project but I do have a big mouth and I am still chewing so until I choke to death on it, I'll keep chewingApart from power plant a pretty much traditional chassis is build. Looks good !

I painted the frame with rust bullet then top coated it with rust bullet black top coat.

I made the tabs for the trailing arms split so they could be welded to the bottom of the frame as well. Don't know how this is normally done and is probably unnecessary but I thought it looked good anyway.

I made the tabs for the trailing arms split so they could be welded to the bottom of the frame as well. Don't know how this is normally done and is probably unnecessary but I thought it looked good anyway.

All good progress

Sure great to follow along this build, getting caught up to what sits in your shop!

Thanks for saying so. I know there is nothing particularly special about what I'm doing but it is all a first for me and this sharing in this thread helps keep me motivated by thinking that there are people out there interested in seeing what comes next. Thanks to all that have taken the time to respond either by post or adding a "thumbs up". It is appreciated.Sure great to follow along this build, getting caught up to what sits in your shop!

Of course we are interested, who wouldn’t be. Keep it coming.

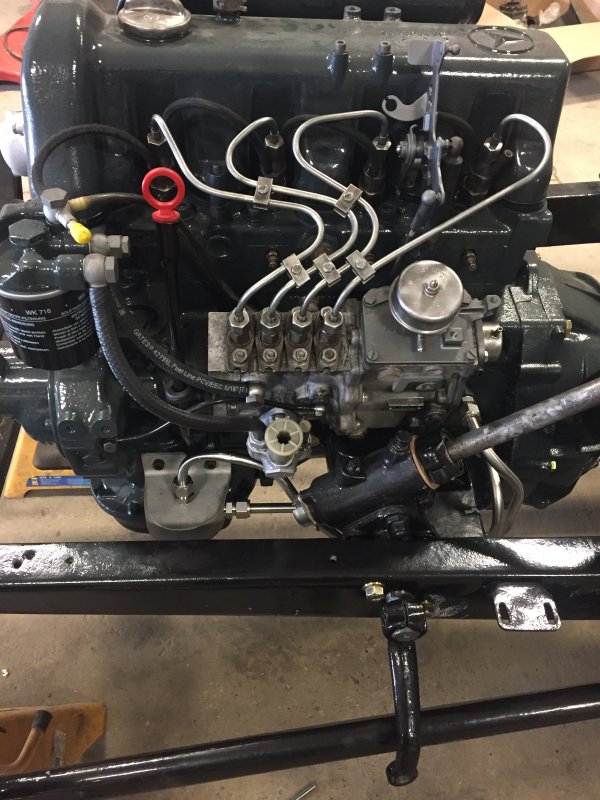

On the mercedes diesel, the oil filter is a large, cartridge affair that bolts to the rear of the block just below and behind the injection pump. It was too big and wouldn't clear the firewall so I had to move it. After figuring out the dires=ction of flow, I made a plate for the mounting pad on the block with nipples aligning the oil in and oil out ports, ran SS tubing to a nice handy location ( that had two unused tapped holes) and made a platform to accommodate a chevy spin on. I was SO upset when I FU the spacing on the holes for the entering the filter but I didn't have any more aluminum shaft that size to make another. I have yet to open up and tap the centre for the nipple but otherwise it's done. However, I've been thinking about it and make make a new one anyway out of steel as i fear that aluminum may be too soft and give me sealing issues with the filter. Also, then I can fix the goofy spacing on the holes.

Building the lower wood. The wood kits are EXPENSIVE so I decided that the lower wood didn't look that difficult and i would just make it. Had a friend that is an accomplished wood worker make the sills then I did the final fitting on the chassis. Took some cyphering to get the ends of the sills right as the ends of the originals were rotted off. Fortunately, they were rotted differently from side to side so by comparing both sides and "filling in the blanks" from one side to the other (and applying a little common sense) we were able to get the ends right. Made it from white oak (as were the originals) with the exception of the rear most cross piece that was thicker than what I had for oak so I bought a piece of ash (also used in the originals) for that one piece.

No idea but I have a spare one of each and could compare. I doubt that there is much difference, 100 pounds at the most In would think and that might be a stretch.A very interesting project. Any idea of the weight difference between the diesel and the original motor?

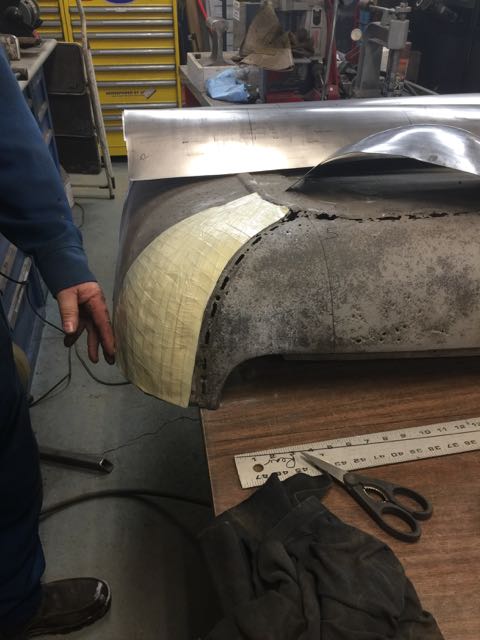

As I mentioned early on in this thread, I took a crash coarse with John (JVO) on panel fabrication. The worst part of the body was rust under the roof fabric so the entire upper portion of the quarter panels had to be replaced. John had posted these pics before but I thought I would repost here to keep the progression of the entire project in one place and for those that may be following but dod not see the earlier thread. I have the pics out of order but the first shows the flexible pattern used to transfer the shape of the original corner to the new one. The last pic is me "gently" massaging the shape and then the others fitting and tacking once the shape conformed to the pattern that we made.

That corner piece must have been difficult to make...nice..

Actually no. With the proper tools and John's tutelage is was relatively easy. The long roof pieces were much more of challenge as they have a crown along the top, a crown along the side, and the radius of the curve gets tighter as it moves forward.That corner piece must have been difficult to make...nice..