|

Some Dash Work

|

|

|

Text

and photos by Bob Klowak

|

|

|

In

the previous pictures we showed this pump assembly from GM. Its a great

idea but not practical to adapt. It requires a rounded lip on the tank

to match the "O" ring . The tank was flat and a poly tank

is difficult to machine in your garage. |

|

|

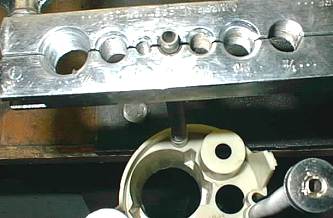

We

removed the top of the assembly ,leaving the 3 stainless tubes. We then

made 3 thick washers out of , what else , 3/16 " plate and made

them with a hole saw. The holes were then enlarged to fit the tubes

snugly leaving the springs between. |

|

Then

the ends of the tubes were flared so the tubes could not slide out of

the washers. |

|

|

With

the mig welder a small tack was made around the tube to secure it . |

|

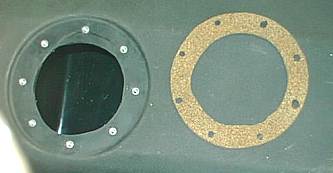

Next a round plate to match the top of the gas tank (where a large fuel

inlet would be used for racing purposes) was made. Material? You guessed

it - 3\16 " plate. We have tons of that stuff around . Matching

holes were drilled and a exit pipe for the fuel was put through the

plate and to the other side. This little adapter was from a skidoo fuel

tank. It was then silver soldered to seal it . |

|

|

A

gasket was then cut out of cork with matching holes . This was a little

tricky but a compass worked well on both the gasket and large metal plate. |

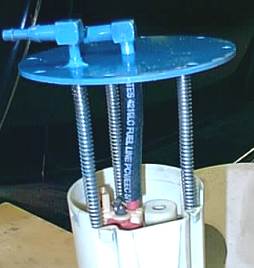

| The

3 thick washers were then mig welded to the plate. Then a return line

was added by drilling a hole to line up with the center of one of the

tubes. Another fuel adapter was put in the hole and silver soldered again.

A rubber fuel hose was added and clamped. An insulated post was added

and wires connected to feed the pump. One of the screws that hold the

pump in the tank will be the ground. |

|

|

The whole assembly was dropped in the hole and bolted. Everything was capped and pressure tested at 2 pounds to check for leaks with soap. None were found. Problem solved . |

|

Copyright

© 2001-2002

canadianrodder.com/eFX Design

|

|