| Getting

To Work On Our Frame |

by Frank Colgoni

First Off: Some Cosmetic Surgery

We mentioned in article one that “custom work

will be kept to a minimum. If, during the build, we

feel that some customization or change will improve

the overall look, performance or distinctiveness of

the car, we will pursue it.”

Well, having said that, what do we start with? Custom

work - of course. After some discussion, we decided

to do a little cosmetic surgery that would affect the

overall length of the frame and specifically the length

of the front frame horns. The stock wheelbase of 106”

remains unaffected.

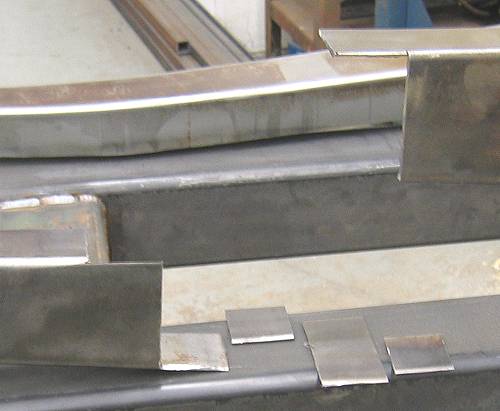

By taking 2” out of the frame rail / frame, and

with the diameter of the front tire that we’re

using (195/65X15), the tip of the frame horns / front

spreader bar ends up almost exactly lined up with the

leading edge of the tire (rather than 2” in front

of it).

To achieve this, and to help maintain the integrity

of the rail /strength, the rail was sectioned by Dream

Machines so that the material removed came out of different

places on the rail top, side and bottom rather than

straight through. |

Our sectioned rail |

By taking out the material at this point, the frame

horn retains its shape. |

Establishing Critical Dimensions

There are a number of ways to establish dimensions when

building a frame from scratch. Obviously, the first way

is to consult a drawing(s) (and we did). If available,

an original frame that hasn’t been altered from

its production dimensions might be another way. Also,

frames from other projects are useful. Proceed with

caution though with all references. Having done

a number of cars with replica bodies, a lesson learned

is to use the body (your body) as another, important,

reference. It is a fact that all bodies are not created

equal – in terms of dimensions that is. In the

case of the ’32 body, there is a natural channelling

that occurs where the body overlaps the frame starting

at the cowl and ending at the rear quarter. Because

of this, the frame must fit in the pocket formed by

this channel. The dimensions of this pocket from your

body can be compared with your reference measurements.

Better to do this than to have the body either not fit

over the frame or be too sloppy.

With new rails like ours, it’s a good time to

compare front to back body mounting locations with the

holes in the top of the frame where weldnuts will be

fastened. Also, side-to-side / centre-to-centre dimensions

of our body mounting locations were noted and struts

were cut to length and holes were drilled at these centre-to-centre

dimensions taken from the body. These will be used to

aid in establishing width. Before the rails go into

the fixture, the weldnuts are fastened to the underside

of the upper rail horizontal. We added an extra body

mounting location location in the middle of the door

opening to allow for additional shimming.

When we were satisfied with our reference measurements,

the fixture laterals (outriggers) were established.

The rails were positioned on the laterals and the side-to-side

struts were loosely fastened to the rails. Spacer blocks

are put under the frame at two lateral positions where

the frame is meant to be parallel with the frame table. |

The rails sit loosely on the outriggers with the struts

in place.

Verticals are being cut and added to each outrigger.

|

|

Pinching Rails

Before proceeding, a few words about pinching the ’32

rails. If you’re not familiar with the term, pinching

refers to the process of bringing the rails closer together

at the front end on highboy frames to eliminate the gap

between the hood and the frame rail toward the front end

of the hood side. This is matter of preference and not

necessary (obviously).

When the rails are pinched, a number of additional

modifications are required: front crossmember width,

rad mounting locations, panhard bar length, spreader

bar width. Our rails will be pinched 7/8” on each

side.

|

An unpinched rail / resulting hood alignment |

The result of pinching |

Securing The Frame Rails To The

Fixture

Before the boxing plates go on, side-to-side dimensions

are established, uprights are attached to the laterals,

the rails are squared, the front frame horns are secured

to a speader bar arrangement that is part of the fixture

(at pinched dimension) and then the rails are tacked to

the uprights. At this stage the boxing of the rails could

begin. With these precautions and a sensible welding sequence,

movement in the rails from the boxing process / heat will

be controlled. |

Vertical are in place and tacked |

Rails have been piched and held in place by fixtured

spreader. |

Boxing The Rails

As the frame is in the fixture, there’s no question

that the boxing process is more difficult. Once the welding

is completed on the boxing plates and crossmembers are

added, the frame can be removed from the fixture. The

welds can then be dressed. |

Rear boxing plate going in |

Intersection of front and rear boxing plates |

|

|

| Next Up - Crossmembers / Intro to front and rear ends |

|