Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

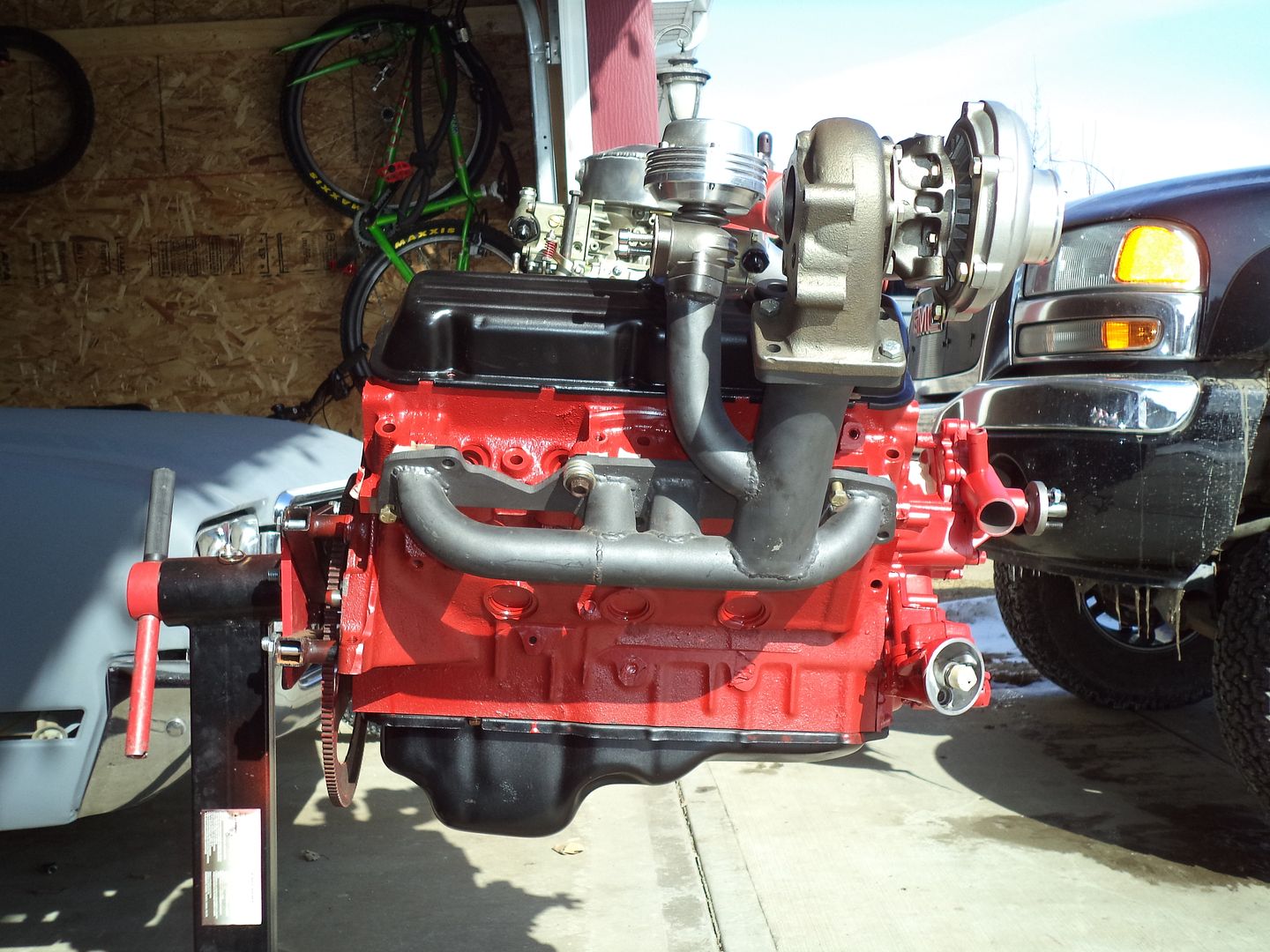

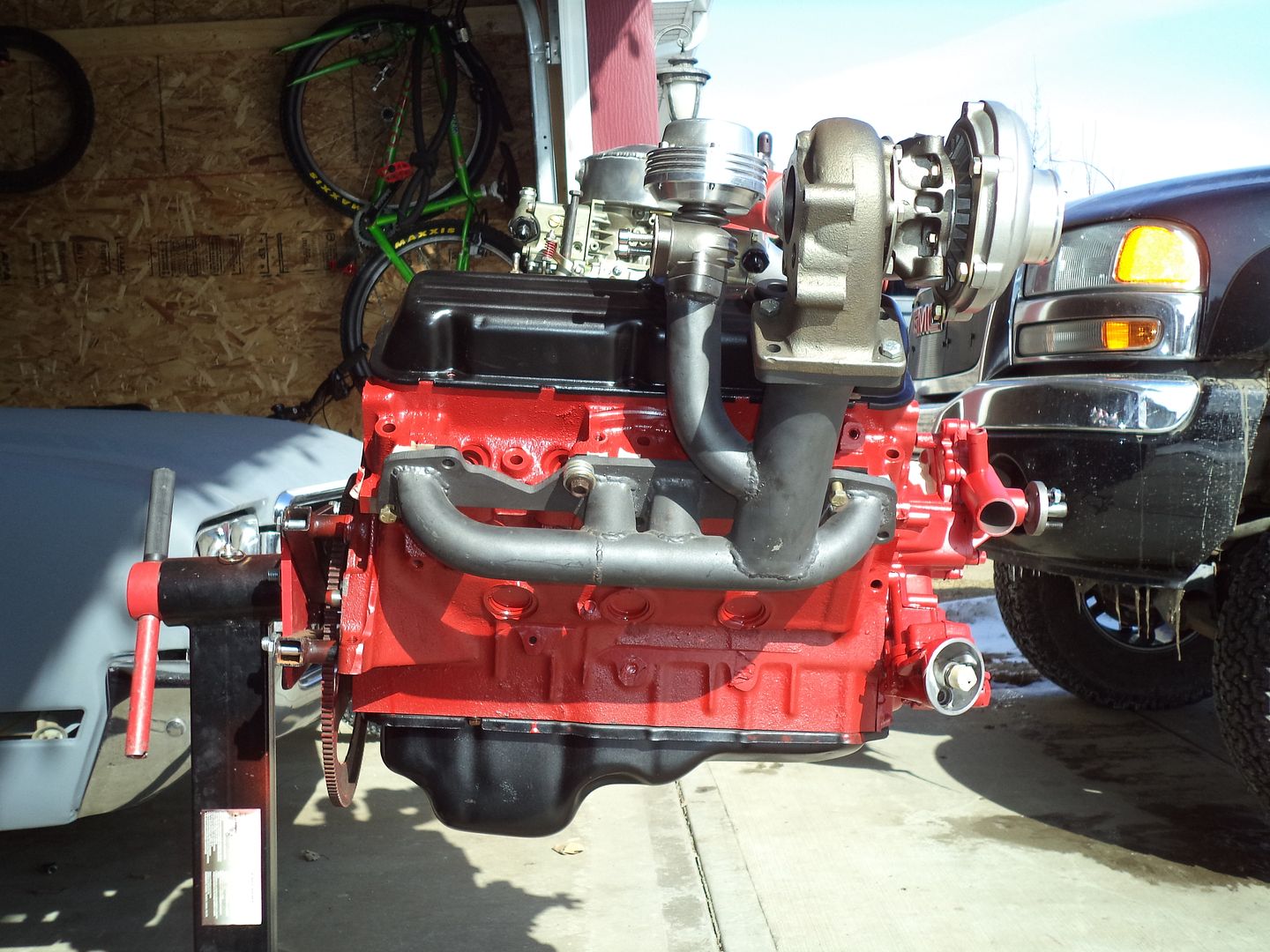

1970 Buick Street/Strip Skylark Build

- Thread starter Twin Turbo Skylark

- Start date

Twin Turbo Skylark

Active Member

Yes, maybe I will do a bit more work in that area... I have been staring at that area and thinking the same thing. I am going to wait a few days till I have more patience for it....

Twin Turbo Skylark

Active Member

bullet

Well-Known Member

Curiousity killed the cat ...... don't know if I'm phrasing this right .......

what happens to the gases or the reaction the gases make at detonation on top of the piston,

with sharp edges vs. smooth and how much does it improve the final output ?

Or are the gases effected at all for improving HP, or are you just removing some dead weight ? And if that's the case, the pistons would then need to be match weighed again

Just curious.

what happens to the gases or the reaction the gases make at detonation on top of the piston,

with sharp edges vs. smooth and how much does it improve the final output ?

Or are the gases effected at all for improving HP, or are you just removing some dead weight ? And if that's the case, the pistons would then need to be match weighed again

Just curious.

Last edited:

Twin Turbo Skylark

Active Member

The reason I am going to all this effort to smooth the pistons is because of the high amount of cylinder pressure that will be present due to the turbochargers, and the fact that turbocharged engines are easily ruined by detonation. The difference between making 600 hp and 700 hp can be determined by the "tune" and if the engine is detonation prone then I could have to keep the boost and timing levels much lower than optimum.

I am bringing my rods, pistons, and crank to my machinist to have him re check the balance however I do not think there will be much if anything done to re balance the assembly. This is a fully internal balance do the flexplate and harmonic balancer are neutral balanced and all the balancing is done internally. These pistons were 555 grams before smoothing and are 553 now, compared to the stock pistons at 740 grams these are much better and more durable.

Here is some info on pre-ignition and "hot spots":

Pre-ignition is a technically different phenomenon from engine knocking, and describes the event wherein the air/fuel mixture in the cylinder ignites before the spark plug fires. Pre-ignition is initiated by an ignition source other than the spark, such as hot spots in the combustion chamber, a spark plug that runs too hot for the application, or carbonaceous deposits in the combustion chamber heated to incandescence by previous engine combustion events.

Typical causes of “hot spots” are sharp edges in the piston head or head chamber.

Pre-ignition and engine detonation both sharply increase combustion chamber temperatures. Consequently, both effect increases the likelihood of the other effect occurring, and both can produce similar effects from the operator's perspective, such as rough engine operation or loss of performance due to operational intervention by a powertrain-management computer. For reasons like these, a person not familiarized with the distinction might describe one by the name of the other. Given proper combustion chamber design, pre-ignition can generally be eliminated by proper spark plug selection, proper fuel/air mixture adjustment, and periodic cleaning of the combustion chambers.

Causes of pre-ignition include the following:

- Carbon deposits form a heat barrier and can be a contributing factor to pre-ignition. Other causes include: An overheated spark plug (too hot a heat range for the application).

- A sharp edge in the combustion chamber or on top of a piston (rounding sharp edges with a grinder can eliminate this cause).

-Sharp edges on valves that were reground improperly (not enough margin left on the edges).

-A lean fuel mixture can also cause this issue.

I am bringing my rods, pistons, and crank to my machinist to have him re check the balance however I do not think there will be much if anything done to re balance the assembly. This is a fully internal balance do the flexplate and harmonic balancer are neutral balanced and all the balancing is done internally. These pistons were 555 grams before smoothing and are 553 now, compared to the stock pistons at 740 grams these are much better and more durable.

Here is some info on pre-ignition and "hot spots":

Pre-ignition is a technically different phenomenon from engine knocking, and describes the event wherein the air/fuel mixture in the cylinder ignites before the spark plug fires. Pre-ignition is initiated by an ignition source other than the spark, such as hot spots in the combustion chamber, a spark plug that runs too hot for the application, or carbonaceous deposits in the combustion chamber heated to incandescence by previous engine combustion events.

Typical causes of “hot spots” are sharp edges in the piston head or head chamber.

Pre-ignition and engine detonation both sharply increase combustion chamber temperatures. Consequently, both effect increases the likelihood of the other effect occurring, and both can produce similar effects from the operator's perspective, such as rough engine operation or loss of performance due to operational intervention by a powertrain-management computer. For reasons like these, a person not familiarized with the distinction might describe one by the name of the other. Given proper combustion chamber design, pre-ignition can generally be eliminated by proper spark plug selection, proper fuel/air mixture adjustment, and periodic cleaning of the combustion chambers.

Causes of pre-ignition include the following:

- Carbon deposits form a heat barrier and can be a contributing factor to pre-ignition. Other causes include: An overheated spark plug (too hot a heat range for the application).

- A sharp edge in the combustion chamber or on top of a piston (rounding sharp edges with a grinder can eliminate this cause).

-Sharp edges on valves that were reground improperly (not enough margin left on the edges).

-A lean fuel mixture can also cause this issue.

bullet

Well-Known Member

Alright .. thanks for that explanation.

Short story on too hot a spark plug.

Many years ago I had a faulty plug in my Harley and was told I could run a 350 SBC plug.

OK, so it was Sunday and I had to work Monday, so I had no other choice but to run the SBC plug.

They failed to tell me that it was a temporary measure and only for a short distance.

I rode from Kamloops to the other side of Hope ( down the Fraser Canyon .. no Coq. Hwy. in them days ) when I lost the rear cylinder in a puff of white smoke.

I limped the rest of the way home ( to Delta ) on the front cylinder, it sounded like a John Deere.

When I removed the rocker box and cylinder barrel, I found a hole the size of a quarter burnt through the piston.

Too hot a plug ... live and learn as they say.

Short story on too hot a spark plug.

Many years ago I had a faulty plug in my Harley and was told I could run a 350 SBC plug.

OK, so it was Sunday and I had to work Monday, so I had no other choice but to run the SBC plug.

They failed to tell me that it was a temporary measure and only for a short distance.

I rode from Kamloops to the other side of Hope ( down the Fraser Canyon .. no Coq. Hwy. in them days ) when I lost the rear cylinder in a puff of white smoke.

I limped the rest of the way home ( to Delta ) on the front cylinder, it sounded like a John Deere.

When I removed the rocker box and cylinder barrel, I found a hole the size of a quarter burnt through the piston.

Too hot a plug ... live and learn as they say.

Last edited:

chris roesch

Member

hello!!

wow, only a handful of guys i know that have an x-factor intake! nice to see you mister G

wow, only a handful of guys i know that have an x-factor intake! nice to see you mister G

Twin Turbo Skylark

Active Member

thanks! I have a deposit on the upcoming TA heads and intake too!

chris roesch

Member

ta is getting us aluminum heads???????? wow is this a dream? post up some pics when you get them... what are you doing with the x factor?

Twin Turbo Skylark

Active Member

Yes you need to call at TA and Leave a deposit on a set of al heads and a single plane intake. I will get the first intake and heads after they are done the prototype phase. The deposit gets me in line for the products when they are done. I am using iron heads on my good engine with the X factor intake and the twin turbos.

I am building another Buick 350 to use with the new heads and intake. I am using a 68 block with a block girdle, forged rods, and it will borrow the twin turbos for dyno testing. The heads will first go to Chris scaling in Canada for a full on port job. NA I hope for 460 hp at 8.5:1 and it will be about 800 hp under boost.. If the engine survives well I will swap it into the street legal skylark.

I am building another Buick 350 to use with the new heads and intake. I am using a 68 block with a block girdle, forged rods, and it will borrow the twin turbos for dyno testing. The heads will first go to Chris scaling in Canada for a full on port job. NA I hope for 460 hp at 8.5:1 and it will be about 800 hp under boost.. If the engine survives well I will swap it into the street legal skylark.

bullet

Well-Known Member

That sounds like it was an expensive lesson to learn.

Russ

Not to take any more away from Skylarks thread, I'll just add this final note.

No Russ, not really, just the cost of a piston ... but it WAS a lesson.

Harley rocker boxes and barrels are easily removed and put back together.

Can do it in less than a hour.

Last edited:

Twin Turbo Skylark

Active Member

No worries, I am glad to hear you got it back together without a major cost!

Twin Turbo Skylark

Active Member

A LITTLE VIDEO OF ENGINE DAY HERE IN ALBERTA

http://www.youtube.com/watch?v=RZXxwcjwfOQ&feature=youtu.be

http://www.youtube.com/watch?v=RZXxwcjwfOQ&feature=youtu.be

Last edited:

Hubcaps for sale

Not mine, but thought you might be interested.

http://www.kijiji.ca/v-classic-cars...aps/576563265?enableSearchNavigationFlag=true

Not mine, but thought you might be interested.

http://www.kijiji.ca/v-classic-cars...aps/576563265?enableSearchNavigationFlag=true

Twin Turbo Skylark

Active Member

Thanks I will check it out

John in Oz

Well-Known Member

Waste Gates Bullet

bullet

Well-Known Member

Waste Gates Bullet

That's what I thought but wasn't sure, don't know much about turbos.

Twin Turbo Skylark

Active Member

Those are waste gates.... They allow extra exhaust to be re routed out the tail pipe instead of going through the turbocharger. Through these waste gates we can control the boost levels and prevent over boosting the engine. They are currently set to 7 psi max boost but I will slowly raise that to about 20 psi.... At 20 psi it should make about 850 hp